- Home

- Advantages Of Cnc Milling

Advantages of CNC Milling: A Comprehensive Guide for Manufacturers

Introducing the cutting-edge CNC milling machine by Guangdong Shunde Teamwork Model Co., Ltd., a leading manufacturer, supplier, and factory based in China. With a focus on precision engineering and technological excellence, our CNC milling machine offers an array of advantages that cater to the ever-evolving industrial needs.

Designed with precision and efficiency in mind, our CNC milling machine utilizes computer numerical control technology, which enables automated and accurate machining operations. This allows for consistent and repeatable results, ensuring high-quality products every time. The advanced control system empowers operators to program complex designs effortlessly, reducing human error and maximizing productivity.

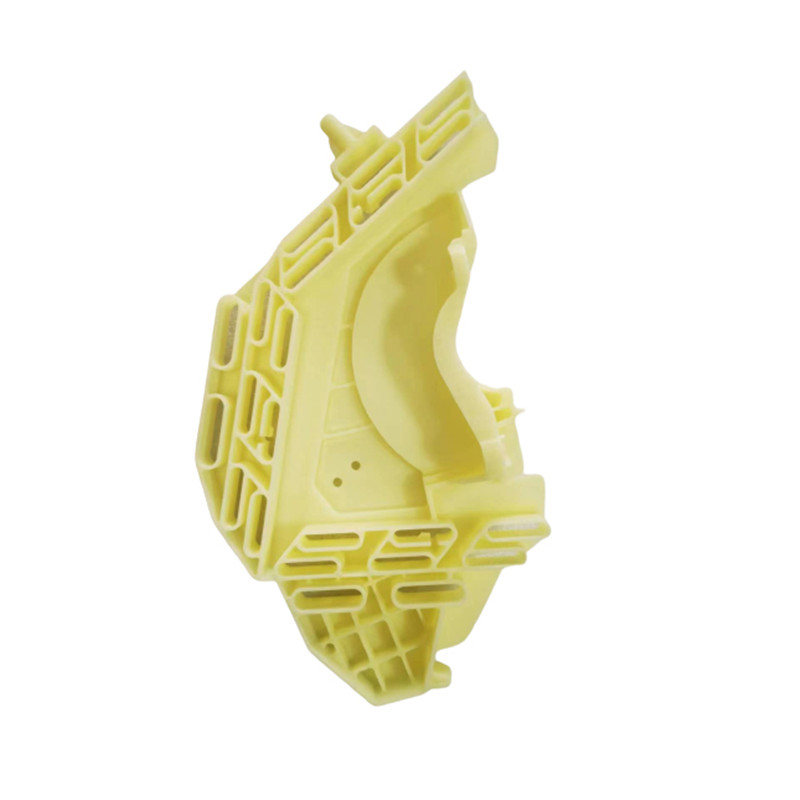

Equipped with state-of-the-art cutting tools and materials, our CNC milling machine guarantees optimal precision and versatility. It seamlessly handles a wide range of materials, including metals, plastics, and composites, offering limitless possibilities for various industries such as automotive, aerospace, and electronics.

Furthermore, our CNC milling machine eliminates the need for multiple machines, reducing setup time and expenses. Its compact design and user-friendly interface make it easily operable, even for novice users.

With the CNC milling machine by Guangdong Shunde Teamwork Model Co., Ltd., you can achieve superior precision, efficiency, and cost-effectiveness, elevating your manufacturing capabilities to new heights. Trust in our commitment to excellence and revolutionize your production process today.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

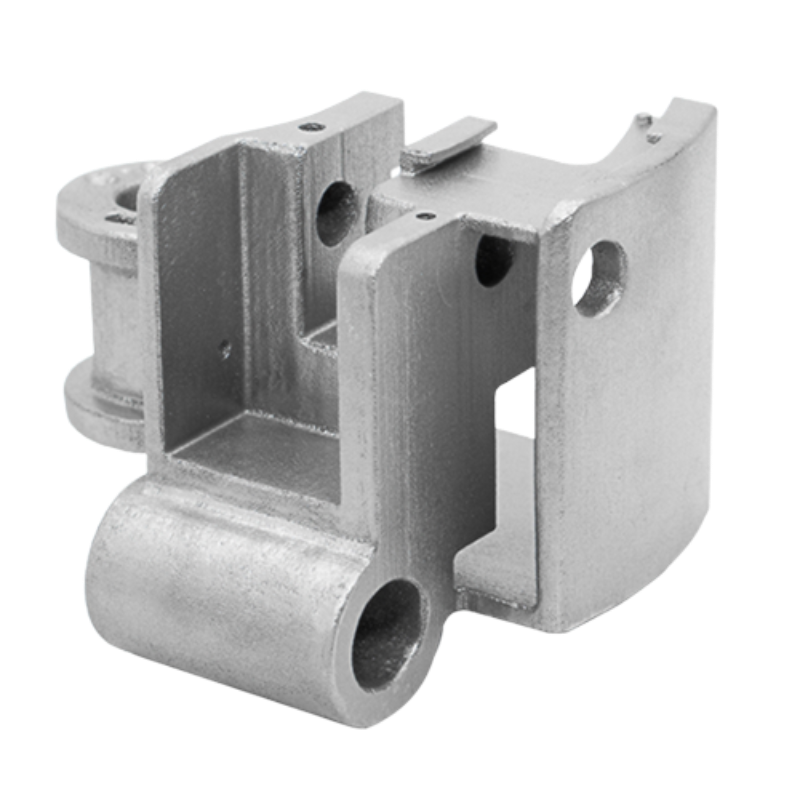

OEM component metal machining parts CNC aluminium factory service

Get premium OEM component metal machining parts at our CNC aluminium factory. We provide reliable and efficient services as a manufacturer.

Customized high-quality 3D printing plastic service Chinese prototype factory

Looking for customized high-quality 3D printing plastic services? Look no further! Our Chinese prototype factory offers top-notch manufacturing capabilities and unbeatable prices. Contact us now!

OEM Chinese Customized 3d printed SLA SLS Automotive Prototype Factory

Explore high-quality automotive prototypes at our OEM Chinese Customized 3D Printed SLA SLS Factory. We specialize in delivering precision prototypes for various automotive applications.

OEM Manufacturing Automotive Parts Precision CNC Aluminum Machining Parts

Get high-quality OEM manufacturing automotive parts with precision CNC aluminum machining from our factory. Our expert team ensures optimal performance and durability. Contact us today!

OEM 3D Printing Rapid prototyping SLA SLS Printing Service Manufacturer in China

Choose our {OEM 3D Printing} service for superior {Rapid prototyping SLA SLS Printing}! We are a leading manufacturer and factory in China, providing high-quality printing solutions.

High Precision SLA Printing 3D Printing ABS Rapid Prototype

Get high precision ABS rapid prototype parts with our professional 3D printing service. We are a factory providing SLA printing for excellent quality results.

Customized reliable quality CNC machining plastic prototype

Get premium quality CNC machined plastic prototypes tailored to your specifications from our trusted factory. Experience exceptional reliability and customization in each product.

Custom Zinked Steel Sheet Metal Components

Looking for top-quality custom zinked steel sheet metal components? Look no further! As a factory, we offer durable, precision-crafted products to meet your needs.

OEM Service CNC Aluminum Machining Parts Sandblasting Prototyping

Shop high-quality OEM service CNC aluminum machining parts with sandblasting prototyping at our factory. Perfect for all your manufacturing needs.

Custom precision CNC machining brass part service manufacturer

Looking for custom precision CNC machining brass parts? Our factory specializes in manufacturing high-quality products to meet your specific needs. Contact us today!

Sheet Metal Fabrication Aluminum Enclosure Laser Cutting Bending Stamping Parts

Looking for high-quality sheet metal fabrication parts like aluminum enclosures, laser-cutting, bending, stamping? Our factory provides top-notch customization and excellent service.

Precision sheet metal laser cutting service manufacturer

Experience precise sheet metal laser cutting with our factory's high-quality services. Choose us as your trusted manufacturer for superior precision and craftsmanship.

Custom Precision CNC Machined Aluminum Sandblasting Parts Manufacturing

Choose our factory for top-notch precision CNC machined aluminum sandblasting parts manufacturing. Enjoy high-quality products tailored to your needs!

OEM precision 3D printed metal parts service manufacturer

Looking for top-quality OEM precision 3D printed metal parts? Look no further! As a factory, we specialize in manufacturing high-quality products. Get in touch today!

OEM cnc sheet metal bending laser cutting service manufacturer

Get exceptional OEM CNC sheet metal bending and laser cutting services from our factory. We are a reliable manufacturer delivering top-notch solutions.

- Advantages of CNC Milling: Manufacturer Spotlight

- Reviews

- Related Videos

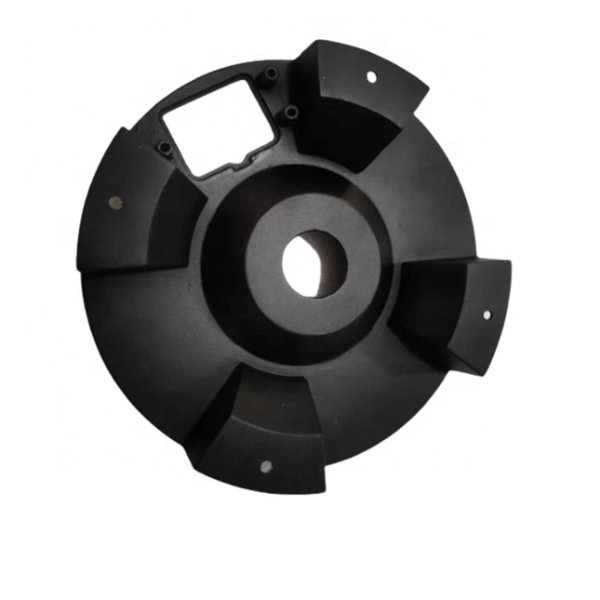

Introducing our latest innovation in manufacturing technology - CNC milling machines. These cutting-edge machines offer numerous advantages and are revolutionizing the way products are fabricated. One of the key advantages of CNC milling is its precision. With these machines, intricate and complex shapes can be achieved with utmost accuracy. The cutting tools attached to the milling machines follow programmed instructions, ensuring consistent and precise cuts every time. This eliminates human error and guarantees high-quality finished products. Speed is another major advantage of CNC milling. These machines can operate at incredibly fast speeds, greatly reducing production time. With their ability to perform multiple tasks simultaneously, they can swiftly undertake complex operations that would take much longer using traditional milling methods. This increased efficiency translates into improved productivity and reduced lead times, enabling businesses to meet customer demands promptly. CNC milling machines are also highly versatile. They can work with a wide range of materials including metals, plastics, wood, and composites, making them suitable for various industries. Whether you need to create intricate automotive parts or custom prototypes, these machines can handle the job effectively. This versatility makes CNC milling an ideal choice for manufacturers looking to diversify their product offerings. Furthermore, these machines are cost-effective in the long run. While the initial investment may be higher compared to traditional milling machines, CNC milling offers enhanced productivity, reduced labor costs, and minimal material wastage. With less need for manual intervention, businesses can reallocate resources to other areas while ensuring consistent output quality. In summary, CNC milling machines provide numerous advantages such as precision, speed, versatility, and cost-effectiveness. By investing in this advanced technology, businesses can streamline their manufacturing processes, enhance productivity, and stay competitive in today's fast-paced market.

CNC milling offers numerous advantages that make it a highly sought-after manufacturing process. With its precision and accuracy, CNC milling ensures consistently high-quality products. The automation aspect reduces the need for manual labor, thus minimizing human error and increasing efficiency. This technology also allows for complex shapes and intricate designs to be effortlessly produced. CNC milling is not limited to any specific material, making it versatile for various industries. Furthermore, it enables cost-effectiveness by reducing waste material and conserving valuable resources. Overall, the advantages of CNC milling make it an indispensable tool in modern manufacturing, offering exceptional quality and efficiency.

CNC milling machines have revolutionized the manufacturing industry with their numerous advantages. One major advantage is the precision and accuracy they offer. With computer-controlled movements, these machines can produce complex and intricate designs with utmost accuracy. Another advantage is the speed and efficiency of CNC milling. These machines can quickly produce multiple parts simultaneously, reducing production time and increasing productivity. Additionally, they can work continuously without human intervention, saving labor costs. Moreover, CNC milling machines are versatile and can work with a wide range of materials like plastic, metal, and wood. This flexibility makes them suitable for various industries and applications. In conclusion, the advantages of CNC milling machines, including precision, speed, efficiency, and versatility, make them a worthwhile investment for any manufacturing business.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours