- Home

- Advantages Of Sls 3d Printing

Top Advantages of SLS 3D Printing: A Complete Guide for Manufacturers

Introducing SLS 3D Printing: Revolutionizing Manufacturing with Unparalleled Benefits

Welcome to the world of SLS 3D printing, a groundbreaking technology that is shaping the future of manufacturing. Guangdong Shunde Teamwork Model Co., Ltd., a leading manufacturer, supplier, and factory in China, is proud to present this innovative solution that offers numerous advantages.

SLS, or Selective Laser Sintering, brings a whole new level of efficiency and precision to the manufacturing process. By using laser technology to fuse powdered materials together layer by layer, SLS 3D printing allows for intricate and complex designs that were previously impossible to achieve.

One significant advantage of SLS 3D printing is its versatility. It can work with a wide range of materials, including plastics, metals, and composites, giving manufacturers the flexibility to create components that meet their specific requirements.

Moreover, SLS 3D printing eliminates the need for costly molds or tooling, saving both time and resources. This not only accelerates the production process but also reduces production costs significantly.

Furthermore, the additive nature of SLS 3D printing ensures minimal material wastage, making it an environmentally friendly choice for sustainable manufacturing practices.

With SLS 3D printing from Guangdong Shunde Teamwork Model Co., Ltd., manufacturers can unlock endless possibilities and propel their businesses to new heights. Experience the future of manufacturing today!

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

Sheet metal fabrication metal stamping manufacturer

Choose our trusted factory for superior sheet metal fabrication and metal stamping services. Our premium products meet your manufacturing needs.

Customized 3D Printing ABS Plastic Parts SLA Printing Rapid Prototype

Get high-quality customized 3D printing ABS plastic parts using SLA printing technology from our factory. We offer rapid prototypes and impeccable craftsmanship.

Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory

Looking for a reliable and experienced CNC machining factory for rapid prototype ABS plastic parts? Our {Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory} is your ideal choice.

OEM CNC machining prototype service PC plastic 3D printing parts service

Experience superior OEM CNC machining prototype service and PC plastic 3D printing parts service. As a factory, we provide top-notch quality and efficiency.

Customized metal parts stainless steel part stretching&spinning factory OEM service

Looking for customized metal parts? Our stainless steel part stretching and spinning factory offers top-notch OEM service. Contact us now!

OEM high-quality galvanized steel sheet metal bending service

Get OEM high-quality galvanized steel sheet metal bending service from our factory. We offer precise, reliable and efficient bending solutions for various industries.

Custom precision rapid prototype ABS plastic 3D printing parts services

Factory-direct custom precision 3D printing services for ABS plastic parts. Fast prototype production. Contact us for quality rapid prototyping solutions.

Custom precision CNC machining brass part service manufacturer

Looking for custom precision CNC machining brass parts? Our factory specializes in manufacturing high-quality products to meet your specific needs. Contact us today!

Precision Sheet Metal Zinked Steel Fabricator Laser Cutting Parts Bending Prototype

Precision Sheet Metal Fabricator - Expert in laser cutting, bending & prototype manufacturing. Factory-direct production of zinc-coated steel parts.

OEM component metal machining parts CNC aluminium factory service

Get premium OEM component metal machining parts at our CNC aluminium factory. We provide reliable and efficient services as a manufacturer.

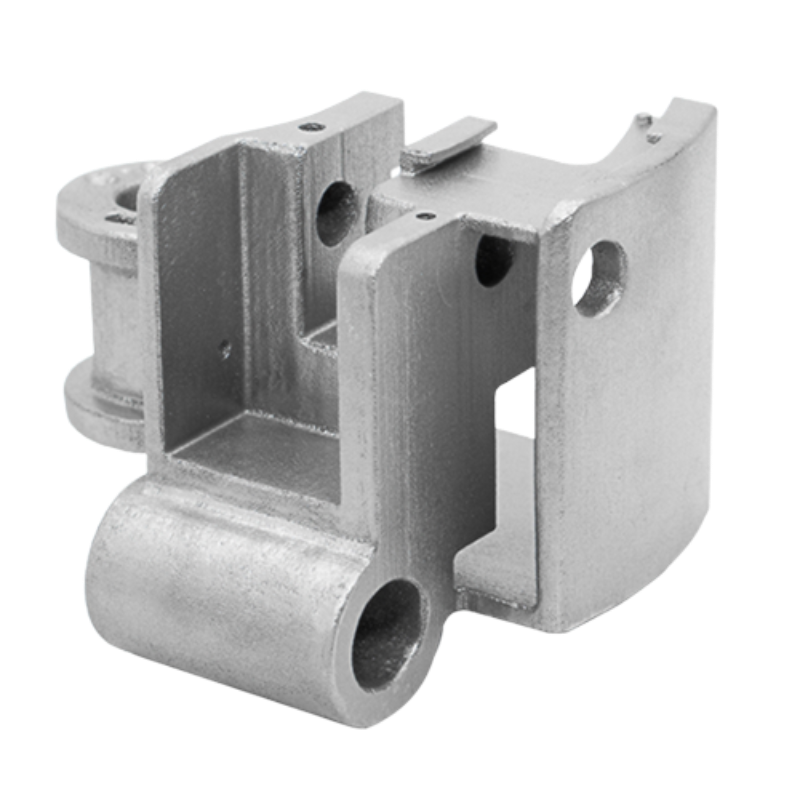

OEM precision 3D printed metal parts service manufacturer

Looking for top-quality OEM precision 3D printed metal parts? Look no further! As a factory, we specialize in manufacturing high-quality products. Get in touch today!

Sheet Metal Fabricator Stamping Parts Laser Cutting Service

Choose our efficient and reliable Sheet Metal Fabricator Stamping Parts Laser Cutting Service. As a factory, we ensure quality craftsmanship and quick turnaround times.

High Precision SLA Printing 3D Printing ABS Rapid Prototype

Get high precision ABS rapid prototype parts with our professional 3D printing service. We are a factory providing SLA printing for excellent quality results.

Custom Zinked Steel Sheet Metal Components

Looking for top-quality custom zinked steel sheet metal components? Look no further! As a factory, we offer durable, precision-crafted products to meet your needs.

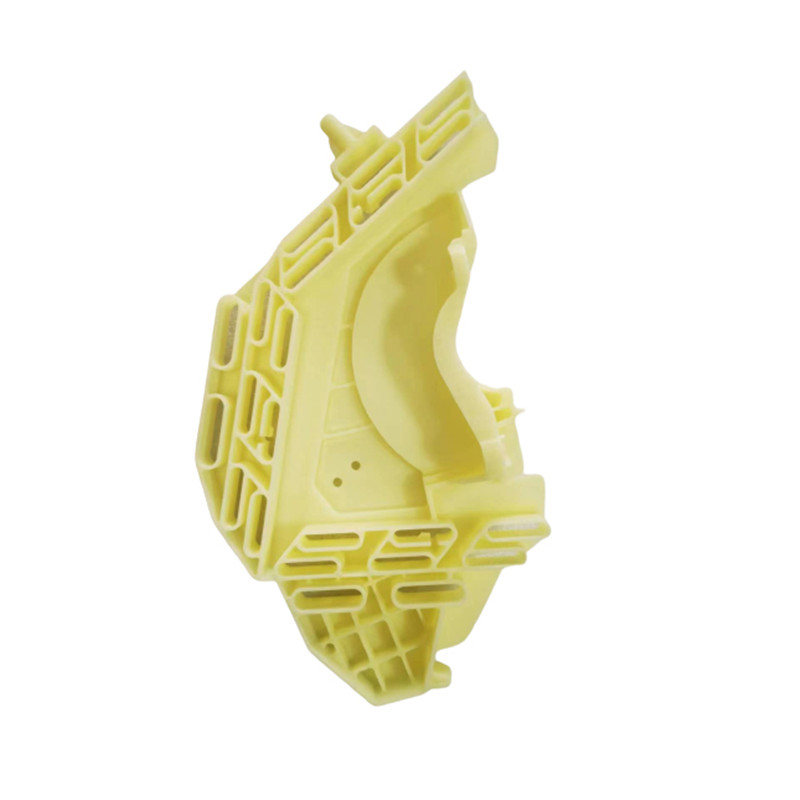

New High Preformance 3D Printing SLS PLA Nylon Model Sample Prototype

Get top-notch SLS PLA Nylon model sample prototypes from our factory. Experience the ultimate high performance 3D printing technology for your projects.

- Top Advantages of SLS 3D Printing - The Ultimate Guide for Manufacturers

- Reviews

- Related Videos

Introducing the revolutionary SLS 3D Printing technology, a game-changer in the world of manufacturing. With its numerous advantages, this innovative technique is set to transform the way products are created. One of the key advantages of SLS 3D Printing is its ability to produce objects with intricate designs and complex geometries. Unlike traditional manufacturing methods, SLS 3D Printing can easily create intricate details and intricate internal structures, resulting in highly sophisticated and precise end-products. Another advantage of SLS 3D Printing is its versatility in material choice. This technology can work with various materials including plastics, metals, and even ceramics. This flexibility allows for the production of a wide range of products, customized to meet specific requirements and applications. Compared to other 3D printing techniques, SLS offers improved strength and durability. By using a laser to sinter powdered materials together, SLS creates objects with strong intermolecular bonds, resulting in robust and resilient final products. This enhanced durability makes SLS 3D Printing ideal for industries and applications where strength is crucial, such as aerospace, automotive, and healthcare. Additionally, SLS 3D Printing provides faster production times. With its no need for support structures, this technology eliminates time-consuming post-processing steps, reducing production time significantly. This efficiency advantage makes SLS 3D Printing suitable for rapid prototyping and short-run manufacturing. In conclusion, SLS 3D Printing is a groundbreaking technology that offers numerous advantages in the manufacturing industry. From intricate designs to wide material choice, improved strength to faster production times, this technology is transforming the way products are made. Embrace SLS 3D Printing and unlock a world of possibilities in design, customization, and efficiency.

SLS 3D printing offers numerous advantages that make it a game-changer in the manufacturing industry. Firstly, it allows for the creation of complex and intricate designs that traditional manufacturing methods struggle with. This technology also offers a wide range of materials to choose from, including strong and durable options like nylon and glass-filled nylon. Another significant advantage is the ability to print multiple products simultaneously, reducing production time and costs. SLS 3D printing is also known for its high level of accuracy and precision, resulting in superior quality products. Overall, this innovative technology is revolutionizing manufacturing processes, providing efficient and cost-effective solutions for various industries.

SLS 3D printing offers numerous advantages that make it a game-changer in the world of additive manufacturing. One of the key benefits of SLS is its ability to produce highly complex and intricate designs with ease. Unlike traditional manufacturing methods, SLS allows for the creation of complex geometries, enabling designers to bring their wildest ideas to life. Moreover, SLS printing eliminates the need for support structures, saving time and reducing material wastage. Additionally, SLS is compatible with a wide range of materials, including nylon, polycarbonate, and even metal, making it suitable for a variety of applications. The accuracy and strength of SLS-printed parts further add to its appeal. Overall, SLS 3D printing offers unmatched flexibility, speed, and precision, making it the go-to choice for professionals in various industries.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours