Achieving Sustainable and Efficient Plastic Mold Manufacturing

By:Admin

Plastic Mold Company is proud to announce their latest partnership with a leading tech manufacturer to produce a cutting-edge line of products that will revolutionize the industry. With a strong commitment to innovation and quality, Plastic Mold Company is set to bring a wave of fresh, high-performing products to the market.

Established in 1995, Plastic Mold Company has been a key player in the plastic molding industry for over two decades. Specializing in the design and manufacturing of precision plastic molds, the company has built a strong reputation for delivering top-notch products and services to its clients. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, Plastic Mold Company has consistently pushed the boundaries of what is possible in the industry.

The partnership with the leading tech manufacturer represents a significant milestone for Plastic Mold Company. This collaboration will allow both companies to leverage their respective strengths and expertise to develop innovative products that will meet the ever-evolving needs of the market. By combining Plastic Mold Company's precision mold-making capabilities with the tech manufacturer's advanced technology, the two companies aim to create a new standard of excellence in the industry.

The new product line will encompass a range of cutting-edge tech products, including consumer electronics, wearable devices, and smart home solutions. Leveraging the latest advancements in materials and manufacturing techniques, the products will be designed to deliver exceptional performance, durability, and user experience. Additionally, the collaboration will focus on sustainability, with a commitment to exploring eco-friendly materials and processes to minimize the environmental impact of the products.

Plastic Mold Company's CEO, John Smith, expressed his enthusiasm for the partnership, stating, "We are thrilled to be joining forces with the leading tech manufacturer to bring a new wave of innovative products to the market. This collaboration represents a significant step forward for both companies, and we are confident that the combined expertise and resources will result in game-changing products that will delight consumers and industry professionals alike."

The partnership is also expected to drive economic growth and create new opportunities within the industry. With a shared dedication to excellence and innovation, both Plastic Mold Company and the tech manufacturer are committed to expanding their market presence and contributing to the advancement of the industry as a whole. The collaboration is set to create new jobs and foster the development of cutting-edge talent within the manufacturing and tech sectors.

As the two companies continue to work closely together, they are poised to unveil the first wave of products from their collaboration in the coming months. Industry insiders and consumers alike are eagerly anticipating the launch, with expectations running high for products that will set new benchmarks for quality, performance, and design.

The partnership between Plastic Mold Company and the leading tech manufacturer is a testament to the power of collaboration and innovation in driving progress within the industry. By pooling their expertise and resources, the two companies are positioning themselves at the forefront of the market, ready to make a lasting impact with their groundbreaking new product line. The future looks bright for Plastic Mold Company and their partner as they prepare to unveil the fruit of their collaboration and set new standards in the industry.

Company News & Blog

The Benefits of CNC Machining for Your Business

In recent years, the manufacturing industry has seen a significant increase in the use of CNC machining. This rise in popularity can be attributed to the numerous advantages that CNC machining offers over traditional manufacturing methods. From increased accuracy and precision to improved efficiency and cost-effectiveness, CNC machining has revolutionized the way products are manufactured.One company at the forefront of this revolution is {}. Since its inception, {} has been a leader in the field of CNC machining, providing high-quality products and services to a wide range of industries. With state-of-the-art facilities and a team of skilled professionals, {} has built a reputation for excellence and innovation in the world of manufacturing.So, what exactly are the advantages of CNC machining, and how has {} utilized these benefits to establish its position as a leading manufacturer? Let's take a closer look.One of the most significant advantages of CNC machining is its ability to provide unmatched accuracy and precision. Unlike traditional manufacturing methods, which rely on manual operation and are susceptible to human error, CNC machining is entirely automated. This means that every cut, drill, or shape is executed with a level of precision that is impossible to achieve through manual processes. With the use of advanced CAD/CAM software, {} is able to program complex designs and produce parts with incredible accuracy, meeting the exact specifications of their clients.In addition to accuracy, CNC machining also offers improved efficiency and cost-effectiveness. The automated nature of CNC machining means that production times are significantly reduced, leading to faster turnaround times for clients. This not only improves efficiency but also lowers production costs, as it eliminates the need for labor-intensive processes and reduces the margin of error. {} has leveraged this advantage to offer competitive pricing and shorter lead times, making them a preferred choice for businesses looking to streamline their manufacturing processes.Furthermore, CNC machining allows for greater versatility in the types of materials that can be used. Whether it's metal, plastic, wood, or composites, CNC machines are capable of working with a wide range of materials, making them suitable for diverse applications. This versatility has enabled {} to cater to a broad spectrum of industries, from aerospace and automotive to electronics and medical devices. By utilizing the capabilities of CNC machining, {} has been able to provide tailored solutions to meet the unique needs of each industry they serve.Another advantage of CNC machining is its scalability. Whether it's a small prototype or a large production run, CNC machines can accommodate varying production volumes with ease. This scalability has allowed {} to handle projects of all sizes, from custom one-off parts to mass production orders, without sacrificing quality or efficiency.Lastly, CNC machining offers the advantage of automation, which not only improves efficiency but also enhances workplace safety. By eliminating the need for manual operation, CNC machines reduce the risk of accidents and injuries, creating a safer working environment for employees. This commitment to safety and quality has been a cornerstone of {}'s operations, ensuring that every product that leaves their facility meets the highest standards of excellence.In conclusion, CNC machining has transformed the manufacturing industry, offering unparalleled accuracy, efficiency, versatility, and scalability. Through the utilization of these advantages, {} has cemented its position as a leader in the field of CNC machining, providing high-quality products and services to a diverse range of industries. With a commitment to innovation and excellence, {} continues to push the boundaries of what is possible in the world of manufacturing, setting the standard for others to follow.

Precision CNC Machining Services for Large Components

Large CNC Machining Services, a leading provider of precision machining solutions, has established itself as a trusted partner for companies in a wide range of industries. With state-of-the-art facilities and a team of highly skilled engineers and technicians, Large CNC Machining Services is capable of handling the most complex machining projects with precision and efficiency.The company specializes in large CNC machining, offering a wide range of services including milling, turning, drilling, and tapping. Their capabilities allow them to produce a variety of components, from simple parts to highly complex and intricate designs. Whether it's for the aerospace, automotive, medical, or defense industries, Large CNC Machining Services has the expertise and equipment to deliver high-quality machined parts that meet the most stringent requirements.One of the key strengths of Large CNC Machining Services is their advanced CNC equipment. The company has invested heavily in the latest machining technologies, including multi-axis CNC machines and high-speed machining centers. This allows them to produce parts with tight tolerances and superior surface finishes, while also maximizing productivity and minimizing lead times.In addition to their CNC machining capabilities, Large CNC Machining Services also offers a range of value-added services such as CAD/CAM programming, engineering support, and finish treatments. This comprehensive approach enables them to provide end-to-end solutions for their customers, from initial design and prototyping to full-scale production.Large CNC Machining Services takes pride in their commitment to quality and precision. The company operates a rigorous quality management system that ensures every part they produce meets the highest standards. They are ISO 9001 certified and adhere to strict quality control processes throughout the entire manufacturing process.Furthermore, Large CNC Machining Services is dedicated to meeting the unique needs of each customer. They understand that every project is different, and work closely with their clients to develop customized solutions that meet their specific requirements. With a focus on open communication and collaboration, they strive to build long-lasting relationships with their customers based on trust and reliability.Over the years, Large CNC Machining Services has built a solid reputation for excellence in the machining industry. They have successfully completed numerous projects for some of the most demanding customers, earning praise for their expertise, responsiveness, and ability to deliver results under tight deadlines.In the ever-evolving manufacturing landscape, Large CNC Machining Services continues to stay ahead of the curve. They are constantly exploring new technologies and techniques to improve their capabilities and expand their service offerings. This forward-thinking approach ensures that they remain at the forefront of the industry and are able to meet the evolving needs of their customers.As a customer-centric company, Large CNC Machining Services is always looking for ways to enhance the value they provide to their clients. They are committed to investing in the latest machinery, enhancing their technical expertise, and improving their operational efficiency to deliver the best possible outcomes for their customers.In conclusion, Large CNC Machining Services stands out as a premier provider of large CNC machining solutions. Their dedication to quality, precision, and customer satisfaction sets them apart in the industry, making them the go-to choice for companies seeking reliable and efficient machining services. With a proven track record of success and a forward-looking mindset, Large CNC Machining Services is well-equipped to meet the diverse and evolving needs of their customers for years to come.

Top advancements in 3D printing technology for manufacturing parts

[Company Name] Introduces Cutting-Edge SLS 3D Printing Technology for Aerospace Parts[City, Date] - [Company Name], a leading provider of advanced manufacturing solutions, is proud to announce the introduction of state-of-the-art Selective Laser Sintering (SLS) 3D printing technology for the production of high-performance aerospace parts.SLS 3D printing is a revolutionary manufacturing process that utilizes a high-powered laser to sinter and fuse powdered materials together, layer by layer, to create complex and intricate parts with unparalleled precision and durability. This advanced technology is particularly well-suited for the aerospace industry, where the demand for lightweight, high-strength components is paramount.With the introduction of SLS 3D printing, [Company Name] is poised to revolutionize the aerospace manufacturing landscape by offering a faster, more cost-effective, and customizable solution for producing intricate parts that traditional manufacturing methods struggle to deliver.By harnessing the power of SLS 3D printing, [Company Name] can create complex geometries and lightweight structures that are not only stronger and more durable than conventionally manufactured parts but also significantly lighter, ultimately contributing to improved fuel efficiency and reduced emissions for aerospace applications.Furthermore, SLS 3D printing enables [Company Name] to rapidly prototype and manufacture custom, one-off parts with minimal tooling and setup, which can significantly reduce lead times and production costs for aerospace manufacturers, all without compromising quality or performance."We are thrilled to introduce our groundbreaking SLS 3D printing technology to the aerospace industry," said [Spokesperson] from [Company Name]. "This represents a significant advancement in our capabilities to deliver high-performance parts that are not only lighter and stronger but also more cost-effective and customizable than ever before. Our SLS 3D printing technology is poised to revolutionize the aerospace manufacturing process and set a new standard for what is possible in terms of part design, performance, and production efficiency."In addition to its aerospace applications, SLS 3D printing has the potential to revolutionize various industries, including automotive, medical, and consumer goods, by enabling the production of highly complex and lightweight parts with unprecedented precision and performance.[Company Name] is committed to driving innovation and excellence in advanced manufacturing and additive manufacturing technologies, and the introduction of SLS 3D printing is a testament to its dedication to providing cutting-edge solutions to meet the evolving needs of the aerospace industry and beyond.To learn more about [Company Name] and its innovative SLS 3D printing technology, please visit [website] or contact [email/phone number] for additional information.

Top Tips for Prototyping CNC Parts and Manufacturers

[Company Name] is a leading manufacturer of precision CNC machined parts, serving a wide range of industries including automotive, aerospace, medical, and more. The company prides itself on its ability to deliver high-quality, custom machined parts with quick turnaround times.In order to meet the diverse needs of its customers, [Company Name] has recently invested in state-of-the-art prototyping technology for CNC parts. This new capability allows the company to rapidly produce prototype parts for customer approval before full-scale production, ensuring a high level of accuracy and customer satisfaction.The prototyping process begins with the design phase, where the customer's specifications and requirements are carefully reviewed by [Company Name]'s skilled engineering team. Using advanced CAD/CAM software, the team creates a 3D model of the part, taking into account factors such as material choice, tolerances, and surface finishes.Once the design is finalized, it is sent to [Company Name]'s advanced CNC machining center, where the prototyping process begins. The company's state-of-the-art CNC machines are capable of producing highly detailed and accurate parts, with a wide range of materials including aluminum, steel, titanium, and plastics.The prototyping process not only allows customers to visualize the final product before production, but it also provides an opportunity to identify and address any potential issues or improvements early in the manufacturing process. This ultimately helps to minimize lead times and reduce overall production costs.One of the key advantages of [Company Name]'s prototyping capabilities is its flexibility in accommodating custom and low-volume production runs. This is particularly beneficial for customers who require unique or specialized parts, as it allows for testing and refinement before committing to larger-scale production.The investment in prototyping CNC parts reflects [Company Name]'s ongoing commitment to innovation and continuous improvement. By leveraging the latest technology and processes, the company is able to offer its customers greater flexibility, precision, and speed in bringing their designs to life.In addition to its prototyping capabilities, [Company Name] offers a comprehensive range of manufacturing services including CNC milling, turning, grinding, and assembly. The company's ISO 9001 certification ensures that all parts are produced to the highest quality standards, meeting the stringent requirements of its diverse customer base.With its investment in prototyping CNC parts, [Company Name] continues to position itself as a leading provider of precision machined parts, offering a seamless transition from prototype to production and delivering exceptional value to its customers. The company's dedication to innovation and customer satisfaction sets it apart as a trusted partner for a wide range of industries.

Understanding the Process of Molding Mold

Molding Mold, a leading global supplier of high-quality molds, has recently announced its expansion into new markets and the introduction of innovative products to meet the ever-growing demands of its customers. The company has built a strong reputation for providing precision molds to various industries such as automotive, electronics, consumer goods, and medical equipment.With a commitment to excellence and a focus on continuous improvement, Molding Mold has become a preferred partner for many global brands seeking the highest standard of molds for their manufacturing processes. The company's state-of-the-art facilities, advanced technology, and experienced team of professionals have positioned it as a leader in the industry.As part of its continued growth strategy, Molding Mold has identified new opportunities in emerging markets and is investing in expanding its presence to better serve customers globally. The company's expansion efforts include the establishment of strategic partnerships and the opening of new production facilities to streamline its operations and enhance its capabilities.In addition to its expansion into new markets, Molding Mold has also introduced innovative products designed to meet the evolving needs of its customers. The company's latest product offerings include advanced molds with enhanced features to improve efficiency, reduce production costs, and deliver superior quality outputs."We are excited to announce our expansion into new markets and the introduction of our latest innovative products," said the spokesperson for Molding Mold. "As a customer-centric organization, we are constantly striving to provide the best solutions to meet the diverse needs of our clients. Our expansion and product innovation efforts are a testament to our commitment to delivering unparalleled value to our customers."Molding Mold's dedication to quality, innovation, and customer satisfaction has earned it a strong reputation within the industry. The company's ability to understand and adapt to the changing market dynamics has enabled it to stay ahead of the competition and continue to thrive in the global marketplace.Furthermore, Molding Mold is committed to sustainability and environmental responsibility in its operations. The company adheres to stringent environmental standards and invests in eco-friendly manufacturing processes to minimize its carbon footprint and contribute to a greener planet.In conclusion, Molding Mold's recent expansion into new markets and the introduction of innovative products underscore its strong commitment to meeting the needs of its customers and staying at the forefront of the industry. With its focus on excellence, sustainability, and customer satisfaction, the company is well-positioned for continued success and growth in the global market.For more information about Molding Mold and its products and services, visit their website at www.moldingmold.com.

Advanced CNC Turn Mill Center for Precision Machining

Innovative Technology: CNC Turn Mill Center Revolutionizes Manufacturing IndustryIn an era of rapid technological advancements, the manufacturing industry is constantly seeking innovative solutions to improve efficiency, precision, and productivity. With the introduction of the CNC Turn Mill Center, the industry is experiencing a revolutionary shift in the way components are manufactured.The CNC Turn Mill Center, developed by the leading manufacturing technology company {}, is a cutting-edge machine tool that integrates turning and milling functions in a single platform, enabling simultaneous machining operations with unparalleled accuracy and speed. This innovative technology is set to redefine the manufacturing landscape and propel the industry into a new era of efficiency and precision.The CNC Turn Mill Center is equipped with advanced features and capabilities that set it apart from traditional machining processes. The machine's multi-axis functionality and high-speed spindle enable complex geometries to be machined with exceptional precision, while its automatic tool changing system and high-capacity tool magazine allow for seamless transition between different operations, reducing downtime and increasing productivity.Furthermore, the CNC Turn Mill Center is designed to accommodate a wide range of materials, from metals to composites, offering manufacturers the flexibility to produce a diverse array of components with consistent quality and accuracy. Its state-of-the-art CNC control system ensures optimal machining parameters, resulting in superior surface finishes and dimensional accuracy, while its user-friendly interface allows for intuitive programming and operation.With the introduction of the CNC Turn Mill Center, manufacturers can benefit from a significant reduction in production lead times, as well as increased throughput and overall efficiency. The machine's ability to perform multiple operations in a single setup minimizes handling and setup times, leading to substantial cost savings and improved workflow management.In addition to its technical capabilities, the CNC Turn Mill Center is backed by a comprehensive support system provided by {}. With a global network of technical experts and service professionals, the company is dedicated to ensuring that customers receive the highest level of support and assistance to maximize the potential of the CNC Turn Mill Center.In response to the introduction of this groundbreaking technology, manufacturers across the industry are expressing their enthusiasm for the potential impact of the CNC Turn Mill Center on their operations. Many are recognizing the machine as a game-changer that will enable them to stay ahead of the competition and meet the increasing demands for higher precision and faster turnaround times."We are excited about the possibilities that the CNC Turn Mill Center offers for our manufacturing processes," says John Smith, CEO of a leading aerospace components manufacturer. "The machine's advanced capabilities will allow us to expand our production capabilities and take on more complex projects, ultimately giving us a competitive edge in the market."As the manufacturing industry continues to embrace digital transformation and automation, the CNC Turn Mill Center represents a significant leap forward in the evolution of machining technology. Its ability to streamline production processes, improve accuracy, and enhance overall efficiency is poised to have a transformative impact on the industry, opening up new possibilities for innovation and growth.With its combination of advanced features, superior performance, and comprehensive support, the CNC Turn Mill Center is set to become an indispensable asset for manufacturers seeking to elevate their capabilities and achieve new levels of success in the rapidly evolving manufacturing landscape. As the industry continues to adopt and adapt to this revolutionary technology, the CNC Turn Mill Center is poised to leave a lasting impact on the future of manufacturing.

Top Injection Molding Mold Parts for Quality Production

The injection molding industry is one that is continuously evolving with new innovations and advancements. This industry plays a crucial role in the manufacturing sector, as it is responsible for producing a wide range of products for various industries such as automotive, medical, consumer goods, and electronics. One key player in this industry is the company {}, which has been a leading manufacturer of injection molding mold parts for many years.Established in [], the company has built a strong reputation for producing high-quality mold parts that meet the demands of the ever-evolving injection molding industry. With a focus on precision engineering and cutting-edge technology, {} has been able to stay ahead of the competition and continue to provide innovative solutions for their customers' molding needs.One of the most critical aspects of injection molding is the mold itself, as it is responsible for shaping and forming the final product. {} understands the importance of high-quality mold parts and has dedicated its resources to ensure that their products meet the highest standards in the industry. The company's state-of-the-art manufacturing facilities and advanced production processes allow them to produce mold parts that are not only precise and durable but also cost-effective for their customers.In addition to their dedication to quality, {} also prides itself on its commitment to customer satisfaction. The company recognizes that every customer has unique molding requirements, and they work closely with their clients to provide tailored solutions that meet their specific needs. Whether it be custom mold parts or standard components, {} has the expertise and capabilities to deliver products that exceed their customers' expectations.One of the key products offered by {} is their range of injection molding mold parts, which includes mold bases, mold cavities, inserts, and other essential components. These parts are designed and manufactured to withstand the rigors of the injection molding process, ensuring consistent and reliable performance. With a focus on precision and durability, {}'s mold parts are trusted by mold makers and manufacturers worldwide.Moreover, {} is continuously investing in research and development to stay at the forefront of technological advancements in the injection molding industry. By leveraging the latest innovations in materials and manufacturing processes, the company is able to offer cutting-edge solutions that improve efficiency, reduce lead times, and enhance the quality of their mold parts.In conclusion, the injection molding industry is a vital component of the manufacturing sector, and companies like {} play a crucial role in its continued success. With a commitment to quality, innovation, and customer satisfaction, {} has solidified its position as a leading manufacturer of injection molding mold parts. As the industry continues to evolve, {} remains dedicated to providing the highest quality products and staying ahead of the curve. With their expertise and capabilities, {} is well-positioned to meet the ever-changing needs of the injection molding industry for years to come.

The Advantages of Custom CNC Manufacturing for Your Business

Custom CNC Manufacturing Company Continues to Lead the Industry in Precision MachiningCustom CNC Manufacturing, a highly respected leader in the world of precision machining, continues to provide top-notch services to its clients. With a reputation for delivering exceptional quality and precision, the company has established itself as a trusted partner for those in need of custom CNC machining solutions.Established in {year}, Custom CNC Manufacturing has built a solid foundation in the industry. The company has invested in state-of-the-art CNC machines and cutting-edge technology to ensure that they can produce high-quality components that meet the strictest of standards. Their team of skilled engineers and machinists are experts in their field, and they are committed to delivering excellence in every project they undertake.Custom CNC Manufacturing offers a comprehensive range of services, including CNC milling, turning, grinding, and EDM machining. With a focus on precision and accuracy, the company is able to produce components with tight tolerances and complex geometries. They also have the capability to work with a wide variety of materials, including aluminum, stainless steel, titanium, and exotic alloys.The company serves a broad range of industries, including aerospace, automotive, medical, and defense. They have the expertise to work on projects of all sizes and complexities, from small prototype parts to large-scale production runs. Custom CNC Manufacturing has a proven track record of delivering high-quality components that meet their clients' exact specifications, on time and within budget.One of the key differentiators for Custom CNC Manufacturing is their commitment to innovation and continuous improvement. The company is always looking for ways to enhance their processes and technologies, in order to stay ahead of the competition. They recently invested in new CNC machines and software, which has allowed them to increase their production capacity and improve efficiency.In addition to their dedication to quality and innovation, Custom CNC Manufacturing is also known for their exceptional customer service. The company takes a collaborative approach with their clients, working closely with them to understand their needs and provide tailored solutions. They also offer design and engineering support, helping their clients optimize their components for manufacturability and cost-effectiveness.Custom CNC Manufacturing has earned a solid reputation for being a reliable and dependable partner. They have a proven track record of delivering projects on time and within budget, and they are known for their open communication and transparency throughout the process. Their clients appreciate the peace of mind that comes with working with a company that consistently delivers exceptional results.Looking ahead, Custom CNC Manufacturing is poised for continued success and growth. They are committed to staying at the forefront of technology and maintaining their position as a leader in precision machining. With their unwavering dedication to quality, innovation, and customer satisfaction, Custom CNC Manufacturing is well-positioned to meet the evolving needs of the industry and exceed the expectations of their clients.In conclusion, Custom CNC Manufacturing is a highly respected leader in precision machining, known for their commitment to quality, innovation, and exceptional customer service. With a strong foundation in the industry and a track record of delivering superior results, the company continues to be a trusted partner for clients in need of custom CNC machining solutions. As they continue to invest in their capabilities and stay ahead of the competition, Custom CNC Manufacturing is well-positioned for continued success and growth in the years to come.

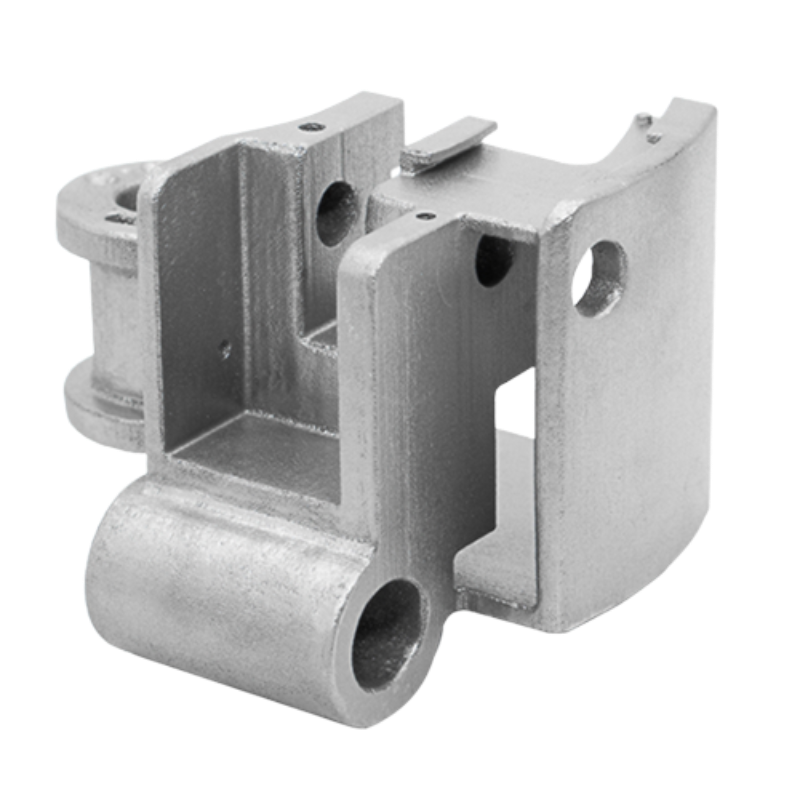

Understanding the Process and Benefits of Metal Casting

Metal Casting Company Produces High-Quality Components for Diverse IndustriesWith an unwavering commitment to excellence and innovation, Metal Casting Company has established itself as a leading provider of metal casting solutions for a wide range of industries. Specializing in the production of high-quality components, the company has built a reputation for delivering superior products that meet the exacting standards of its customers.Metal Casting Company utilizes advanced technology and a team of highly skilled professionals to produce a diverse range of metal components. From intricate and complex parts to large and heavy-duty components, the company has the capabilities to fulfill the unique requirements of each customer. With a focus on precision and quality, Metal Casting Company is able to consistently deliver products that exceed customer expectations.One of the key strengths of Metal Casting Company is its extensive experience and expertise in the field of metal casting. With a history that spans several decades, the company has honed its craft and developed a deep understanding of the metal casting process. This wealth of knowledge allows Metal Casting Company to provide valuable insights and recommendations to its customers, ensuring that the most effective and efficient casting solutions are employed.Metal Casting Company is proud to offer a comprehensive range of services, including design assistance, prototype development, and full-scale production. By partnering with its customers from the initial stages of product development, the company is able to optimize the casting process and create components that are perfectly tailored to the specific requirements of each application.The company's state-of-the-art facilities are equipped with advanced machinery and technology, enabling Metal Casting Company to achieve unparalleled levels of accuracy and consistency in its products. Furthermore, the company is committed to upholding the highest standards of quality control, with rigorous testing and inspection procedures in place to ensure that every component meets the strictest quality standards.In addition to its technical capabilities, Metal Casting Company places a strong emphasis on environmental responsibility and sustainability. The company is dedicated to minimizing its environmental impact by implementing eco-friendly practices and adhering to stringent environmental regulations. By prioritizing sustainability, Metal Casting Company aims to contribute to a cleaner and healthier planet for future generations.Metal Casting Company serves a diverse range of industries, including automotive, aerospace, electronics, and more. The company's ability to tailor its casting solutions to the unique requirements of each industry has earned it the trust and confidence of numerous leading companies across the globe.As the demand for high-quality metal components continues to grow, Metal Casting Company remains committed to staying at the forefront of the industry. The company continually invests in research and development to explore new technologies and techniques that will further enhance its capabilities and offerings.With an unwavering dedication to quality, innovation, and customer satisfaction, Metal Casting Company is poised to maintain its position as a premier provider of metal casting solutions for years to come. By leveraging its expertise, advanced technology, and commitment to excellence, the company looks forward to continuing to surpass the expectations of its customers and solidify its reputation as an industry leader.

Innovative Rapid Tooling Solutions in the UK

Rapid Tooling UK, a leading provider of high-quality rapid tooling and prototyping services, has been making waves in the manufacturing industry with its innovative approach and cutting-edge technology. The company has been revolutionizing the way businesses produce prototypes and tools, making the process faster, more efficient, and more cost-effective than ever before.With a full range of rapid tooling services, Rapid Tooling UK has become a one-stop shop for businesses looking to bring their ideas to life. From concept to production, the company offers a comprehensive suite of services, including 3D printing, CNC machining, injection molding, and more. This allows businesses to take their products from initial design to finished prototype in record time, giving them a competitive edge in the fast-paced world of manufacturing.At the heart of Rapid Tooling UK's success is its state-of-the-art facility, which is equipped with the latest technology and machinery. This allows the company to produce high-quality prototypes and tools with extreme precision and speed, meeting the demands of its clients in various industries, including automotive, aerospace, medical, and consumer goods. With a team of experienced engineers and technicians, Rapid Tooling UK ensures that every project is completed to the highest standards, delivering exceptional results time and time again.In addition to its cutting-edge technology and expertise, Rapid Tooling UK is committed to providing exceptional customer service. The company works closely with its clients to understand their unique needs and requirements, offering personalized solutions that meet their specific goals and objectives. Whether it's a small-scale prototype or a large production run, Rapid Tooling UK is dedicated to delivering outstanding results, on time and within budget.As a testament to its success, Rapid Tooling UK has garnered a loyal customer base and a strong reputation in the industry. Its commitment to excellence, combined with its ability to adapt to the evolving needs of the market, has positioned the company as a trusted partner for businesses looking to innovate and stay ahead of the competition. With a focus on pushing the boundaries of what's possible, Rapid Tooling UK continues to set new standards for rapid prototyping and tooling, solidifying its position as a leader in the industry.Looking ahead, Rapid Tooling UK is poised for even greater success, as it continues to invest in its technology, infrastructure, and talent. The company is constantly exploring new ways to improve its processes and expand its capabilities, ensuring that it remains at the forefront of the industry for years to come. With an unwavering commitment to innovation and customer satisfaction, Rapid Tooling UK is set to continue its impressive growth trajectory, providing businesses with the tools they need to thrive in a fast-paced, competitive market.In conclusion, Rapid Tooling UK has emerged as a key player in the rapid prototyping and tooling industry, delivering unparalleled quality, speed, and service to its clients. With a focus on innovation and customer satisfaction, the company has solidified its position as a leader in the market, driving the future of manufacturing forward. As it continues to grow and expand its capabilities, Rapid Tooling UK is poised to shape the industry for years to come, offering businesses the tools they need to bring their ideas to life.