Durable Sheet Metal Housings: A Cost-Effective Solution for Your Needs

By:Admin

With a strong focus on quality and precision, [Company Name] has established itself as a trusted partner for companies in a wide range of industries, including telecommunications, automotive, aerospace, and medical devices. The company's extensive experience and expertise in sheet metal fabrication make it a go-to choice for businesses looking for high-quality, custom metal components.

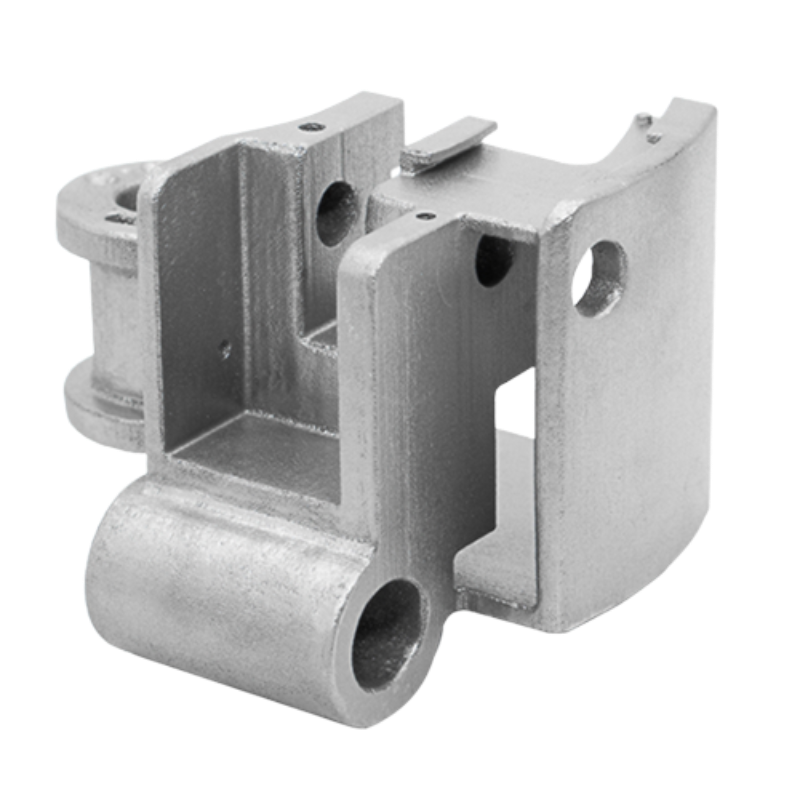

The new sheet metal housings from [Company Name] are manufactured using advanced techniques and state-of-the-art equipment. The result is a product that offers superior durability and protection for sensitive electronic and mechanical equipment. The housings are designed to withstand the rigors of daily use, providing a reliable and long-lasting solution for companies looking to protect their valuable assets.

In addition to their durability, the sheet metal housings from [Company Name] also offer a high level of customization. Customers can choose from a variety of materials, finishes, and designs to create a housing that meets their specific needs and specifications. This level of customization sets [Company Name] apart from other manufacturers, allowing customers to get exactly what they need without compromising on quality or performance.

"Our new sheet metal housings are a testament to our commitment to providing innovative solutions for our customers," said [Company Name] CEO. "We understand the importance of protecting valuable equipment, and our housings are designed to do just that. With their durability and customization options, our customers can trust that their devices will be well-protected in any environment."

In addition to their strength and customization options, the sheet metal housings from [Company Name] are also designed with ease of installation in mind. The company's engineering team works closely with customers to ensure that the housings are easy to integrate into their existing equipment, minimizing downtime and disruption to their operations.

With a focus on quality, customization, and ease of installation, the new sheet metal housings from [Company Name] are set to become a top choice for companies looking for reliable and durable protection for their electronic and mechanical devices. The company's long-standing reputation for excellence in sheet metal fabrication makes them a trusted partner for businesses in a wide range of industries.

"We are proud to introduce our new sheet metal housings to the market," said [Company Name] CEO. "With their unmatched durability, customization options, and ease of installation, we believe they will set a new standard for quality in the industry. We look forward to continuing to provide innovative solutions for our customers' metal component needs."

As [Company Name] continues to push the boundaries of what's possible in sheet metal fabrication, their new housings are just the latest example of their commitment to excellence. With a focus on quality, customization, and customer satisfaction, the company is poised to remain a leader in the industry for years to come.

Company News & Blog

Advanced Vacuum Casting Prototyping for Rapid Product Development

Vacuum Casting Prototyping, a Key Solution for Rapid Product DevelopmentIn today's fast-paced and competitive market, the ability to quickly prototype and test new product designs is crucial for staying ahead of the competition. This is where vacuum casting prototyping comes in, offering a key solution for rapid product development. Vacuum casting prototyping is a highly effective and efficient method for producing small to medium batches of high-quality prototypes and end-use parts. It allows for the quick turnaround of complex parts with tight tolerances, making it an ideal choice for a wide range of industries, including automotive, aerospace, consumer goods, and more.With vacuum casting prototyping, a master pattern is used to create a silicone mold, into which liquid polyurethane is poured and cured under vacuum. This process allows for the production of highly detailed and accurate parts that closely resemble the final product. The ability to produce functional prototypes that can be used for testing and evaluation is invaluable for companies looking to iterate and refine their designs quickly and efficiently.One company that has been at the forefront of vacuum casting prototyping is {Company Name}. With a strong focus on innovation and advanced manufacturing technologies, {Company Name} has established itself as a leader in the field of rapid prototyping and low-volume production. By leveraging the latest advancements in vacuum casting technology, {Company Name} is able to provide its clients with high-quality prototypes and production parts in record time, helping them bring their products to market faster and more cost-effectively.{Company Name} takes a comprehensive approach to vacuum casting prototyping, offering a wide range of materials to meet the specific needs of each project. From rigid and flexible polyurethanes to clear and tinted materials, {Company Name} can produce prototypes with varying mechanical properties, colors, and surface finishes. This versatility allows for the creation of prototypes that closely mimic the look, feel, and function of the final product, giving clients the confidence to move forward with their designs.In addition to its advanced capabilities in vacuum casting prototyping, {Company Name} also prides itself on its commitment to customer satisfaction. With a team of highly skilled engineers and technicians, {Company Name} works closely with its clients to understand their unique requirements and develop tailored solutions that meet their specific needs. Whether it's a complex automotive part, a sleek consumer electronics enclosure, or a medical device prototype, {Company Name} has the expertise and resources to deliver outstanding results.Furthermore, {Company Name} understands the importance of speed in today's business environment. With its streamlined prototyping processes and state-of-the-art manufacturing facilities, {Company Name} is able to deliver prototypes and production parts with short lead times, allowing its clients to meet tight project deadlines and stay ahead of their competition.When it comes to vacuum casting prototyping, {Company Name} is truly a cut above the rest. With its unparalleled expertise, cutting-edge technologies, and unwavering commitment to customer satisfaction, {Company Name} continues to set the standard for rapid product development. Whether it's for prototyping, functional testing, or low-volume production, {Company Name} is the go-to partner for companies looking to bring their innovative ideas to life.In conclusion, vacuum casting prototyping is a crucial tool for companies looking to innovate and stay ahead in today's competitive market. With its ability to produce high-quality prototypes and end-use parts quickly and cost-effectively, vacuum casting prototyping is an invaluable resource for a wide range of industries. And with {Company Name} leading the charge in the field, clients can trust that their prototyping needs are in the best hands.

Custom Metal Printing Service: A New Frontier in Manufacturing

Metal Printing Service Offers Innovative Solutions for Industrial ManufacturingMetal Printing Service is a leading provider of additive manufacturing solutions for industrial applications. With a commitment to delivering high-quality and innovative products, Metal Printing Service has established itself as a trusted partner for companies across various industries.Founded in [Year], Metal Printing Service has quickly become a pioneer in the field of metal 3D printing. The company's state-of-the-art facilities and cutting-edge technology enable them to offer a wide range of services, including prototyping, tooling, and production parts, all with the precision and durability required for industrial manufacturing.One of the key advantages of Metal Printing Service's additive manufacturing processes is the ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This has led to significant cost savings and improved performance for their clients, as well as a reduced time-to-market for new products.In addition to their advanced manufacturing capabilities, Metal Printing Service is known for their strong emphasis on quality control and customer satisfaction. The company's team of engineers and technicians work closely with each client to understand their specific needs and provide tailored solutions that meet or exceed their expectations.Metal Printing Service has also made significant investments in research and development, continually pushing the boundaries of what is possible with metal 3D printing. This commitment to innovation has led to the development of new materials, processes, and applications that further enhance the company's ability to serve their clients.One recent example of Metal Printing Service's innovation is their collaboration with a leading automotive manufacturer to produce a complex component for a new electric vehicle. The component, which required intricate internal channels and precise tolerances, was successfully manufactured using Metal Printing Service's technology, resulting in improved performance and a quicker production timeline for the vehicle.In addition to their work in the automotive industry, Metal Printing Service has also made significant contributions to the aerospace, medical, and energy sectors, providing critical components and prototypes that have helped their clients stay on the cutting edge of innovation.Looking ahead, Metal Printing Service is committed to continuing their growth and leadership in the field of metal additive manufacturing. The company is currently expanding their facilities and capabilities to meet the increasing demand for their services, while also exploring new partnerships and opportunities to further advance the industry.As the manufacturing landscape continues to evolve, Metal Printing Service remains at the forefront of innovation, driving the development of new technologies and applications that are reshaping the industrial manufacturing sector. With their focus on quality, precision, and customer satisfaction, Metal Printing Service is poised to continue delivering groundbreaking solutions for years to come.

Rapid Prototyping and CNC Milling: Everything You Need to Know

In recent years, rapid prototyping and CNC milling have become essential technologies in various industries, allowing companies to prototype and manufacture products quickly and accurately. This has led to significant advances in product development and production, and many companies are continually seeking ways to improve their rapid prototyping and CNC milling capabilities to stay competitive in the market.One company that has been at the forefront of this technological revolution is {}. With a strong focus on innovation and cutting-edge technology, the company has become a leader in providing rapid prototyping and CNC milling services to a wide range of industries, including aerospace, automotive, medical, and consumer electronics. Their dedication to staying ahead of the curve and delivering high-quality, precise parts and prototypes has earned them a stellar reputation in the industry.One of the key factors that set {} apart from its competitors is its investment in state-of-the-art machinery and equipment. By leveraging the latest advancements in rapid prototyping and CNC milling technologies, the company is able to deliver unparalleled precision and efficiency in its manufacturing processes. This has enabled them to take on complex projects that other companies may not have the capabilities to handle, making them a go-to partner for companies looking to bring their ideas to life.Furthermore, {} is committed to providing a seamless end-to-end experience for its clients. From the initial design phase to prototyping and final production, the company offers a comprehensive suite of services to meet the diverse needs of its customers. This holistic approach has allowed {} to build strong, long-lasting partnerships with its clients, as they trust the company to deliver exceptional results every time.In addition to its technical prowess, {} prides itself on its team of highly skilled engineers and technicians. These professionals bring a wealth of knowledge and expertise to every project, ensuring that each part and prototype meets the highest standards of quality and accuracy. By fostering a culture of continuous learning and development, the company stays at the forefront of the latest industry trends and advancements, allowing them to anticipate and adapt to the evolving needs of their clients.Looking ahead, {} remains dedicated to pushing the boundaries of rapid prototyping and CNC milling. The company continues to invest in research and development, exploring new materials, processes, and technologies to further enhance its capabilities and deliver even greater value to its customers. By staying ahead of the curve, {} is well-positioned to remain a leader in the industry and continue shaping the future of manufacturing.In conclusion, rapid prototyping and CNC milling have revolutionized the way products are developed and manufactured. Companies like {} have played a crucial role in driving this transformation, leveraging the latest technologies and a commitment to excellence to deliver exceptional results for their clients. As the demand for rapid prototyping and CNC milling services continues to grow, {} is well-equipped to meet the evolving needs of the market and maintain its position as a trusted partner for companies across a wide range of industries.

Where to Find CNC Business Services Nearby

CNC Business Near Me Offers Precision Machining Services[City, Date] - Precision machining is a critical component of many industries, including aerospace, automotive, and medical. CNC Business Near Me is a leading provider of precision machining services, offering high-quality products with a focus on customer satisfaction. With state-of-the-art equipment and a team of experienced professionals, CNC Business Near Me is committed to delivering precision parts to their clients.CNC Business Near Me specializes in CNC milling and turning, as well as other machining services. The company is known for its ability to meet tight tolerances and deliver complex parts with high accuracy. Their dedication to quality and reliability has earned them a solid reputation in the industry.The company's extensive experience in precision machining allows them to work on a wide range of materials, from aluminum and steel to exotic metals and plastics. They also have the capability to handle both small and large production runs, making them a versatile partner for businesses of all sizes.In addition to their precision machining capabilities, CNC Business Near Me offers value-added services such as assembly, finishing, and inspection. This allows them to provide a complete solution for their customers, from initial design to the final product. Their attention to detail and commitment to quality sets them apart from other machining companies.CNC Business Near Me takes pride in their ability to work closely with their customers to understand their unique requirements. They are known for their responsive customer service and willingness to go the extra mile to ensure customer satisfaction. Their dedication to excellence has led to long-term relationships with many clients, who appreciate their reliability and expertise.The company's commitment to investing in the latest technology and training for their employees has enabled them to stay ahead of the competition. This ensures that they can meet the evolving needs of their customers and continue to deliver high-quality precision parts.CNC Business Near Me understands the importance of sustainability and environmental responsibility. They have implemented green initiatives in their operations, such as reducing waste and energy consumption. They are committed to continuously improving their practices to minimize their impact on the environment.With a focus on continuous improvement and innovation, CNC Business Near Me is well-positioned to meet the growing demand for precision machining services. Their dedication to quality, reliability, and customer satisfaction makes them a trusted partner for businesses seeking precision parts.The company's commitment to excellence and their dedication to customer service have positioned them as a leader in the precision machining industry. Their state-of-the-art equipment, experienced professionals, and focus on sustainability set them apart as a top choice for businesses in need of precision parts.For more information about CNC Business Near Me and their precision machining services, visit their website or contact them directly for a personalized consultation. With a strong reputation for quality and reliability, they are the go-to provider for precision machining services.

High-Quality CNC Turned Components: A Complete Guide

CNC Turned Components: The Future of Precision EngineeringIn today's rapidly evolving manufacturing industry, precision and efficiency are absolutely crucial. This is why industry leaders are increasingly turning to CNC turned components as the key to their success. These components are made with the highest levels of precision and accuracy, and they are revolutionizing the way that companies produce their products.One company at the forefront of this revolution is {}. They have established themselves as a leader in the field of CNC turned components, continually delivering high-quality products to their customers. Their state-of-the-art facility is equipped with the latest CNC technology, allowing them to produce components with the tightest tolerances and the highest quality finishes.With a focus on innovation and continuous improvement, {} is constantly looking for ways to push the boundaries of what is possible in the world of CNC turned components. They work closely with their customers to understand their specific needs and requirements, and then use their expertise to deliver components that exceed expectations.The company's commitment to excellence is evident in everything they do, from the materials they use to the processes they follow. They understand that precision is key in the manufacturing industry, and they take pride in their ability to consistently produce components that are accurate to the smallest detail.One of the key advantages of using CNC turned components is their ability to reduce waste and improve efficiency. By using computer-controlled machines, {} is able to minimize the amount of material that is wasted during the manufacturing process. This not only helps to reduce costs, but it also has a positive impact on the environment.In addition to the environmental benefits, CNC turned components also offer a level of consistency and repeatability that is unmatched by traditional manufacturing methods. This is incredibly important in industries where precision is paramount, such as aerospace, medical devices, and automotive engineering.As the demand for CNC turned components continues to grow, {} is poised to take advantage of this trend by expanding their capabilities and increasing their capacity. They are constantly investing in new technologies and training their staff to ensure that they remain at the cutting edge of the industry.With a focus on precision, efficiency, and innovation, it is clear that CNC turned components are the future of precision engineering. Companies like {} are leading the way in this revolution, and they are committed to delivering the highest quality products to their customers.At {} We're proud to be a leader in the field of CNC turned components and look forward to the continued growth and success of the industry as a whole. Whether it's a custom prototype or a high-volume production run, our team is dedicated to delivering the highest quality components to our customers. Contact us today to learn more about how we can help with your precision engineering needs.

Understanding the Process of CNC Processing

As a leading company in the manufacturing industry, we are constantly striving to incorporate the latest technologies into our processes in order to improve efficiency and quality. In line with this goal, we are excited to announce the implementation of state-of-the-art CNC processing technology at our facilities.CNC processing, or computer numerical control processing, is a advanced manufacturing technique that utilizes computerized controls and machine tools to automate the production of complex parts and components. This technology offers a number of benefits, including higher precision, faster production times, and reduced labor costs.By integrating CNC processing into our operations, we are able to take our manufacturing capabilities to the next level. This technology allows us to produce parts with incredibly tight tolerances, ensuring that every component meets our exacting standards for quality and performance. Additionally, CNC processing enables us to streamline our production processes, resulting in faster turnaround times and more efficient use of resources.One of the key advantages of CNC processing is its versatility. This technology can be used to manufacture a wide range of components, from simple geometries to highly complex shapes. Whether we are producing parts for the aerospace, automotive, or medical industries, CNC processing allows us to meet the unique needs of each customer with ease and precision.Furthermore, the implementation of CNC processing aligns with our commitment to sustainability and environmental responsibility. By optimizing our production processes, we are able to minimize waste and reduce energy consumption, contributing to a more sustainable manufacturing industry as a whole.Through this investment in CNC processing, we are confident that we will be able to better serve our customers and continue to deliver the high-quality products they have come to expect from us. This technology represents a significant step forward for our company, and we are excited about the possibilities it presents for the future of our business.In addition to the implementation of CNC processing, we are also investing in our workforce to ensure that our employees are fully equipped to utilize this technology to its fullest potential. Our team has undergone extensive training to familiarize themselves with CNC processing and to learn how to operate and maintain the new equipment. This ongoing commitment to the development of our employees ensures that we are able to leverage the full capabilities of this advanced technology.As a company that has been at the forefront of the manufacturing industry for many years, we are excited to embrace the opportunities that CNC processing brings. This technology represents a significant advancement in our capabilities, and we are proud to be at the forefront of its adoption in our industry.Moving forward, we are committed to continuing our investment in cutting-edge technologies and processes that will enable us to deliver even greater value to our customers. We believe that the implementation of CNC processing is a testament to our dedication to innovation and excellence, and we are excited about the opportunities it presents for our company and the customers we serve.

High Quality CNC Turning Parts Supplier in China

CNC Turning Parts Industry in China on the RiseChina has been experiencing a significant increase in the demand for CNC turning parts in recent years. As a global leader in manufacturing and technology, China has established itself as a key player in the production of precision components for various industries. With the advancement of CNC technology and the increasing need for high-quality parts, Chinese companies have been thriving in this sector.One such company that has been at the forefront of this development is {}. Specializing in the manufacturing of precision CNC turning parts, they have been supplying top-quality components to a wide range of industries including automotive, aerospace, medical, and electronics. With a strong focus on research and development, they have been able to stay ahead of the competition by continually improving their products and processes.With a state-of-the-art facility equipped with the latest CNC machines and a team of highly skilled engineers and technicians, {} has been able to meet the growing demand for precision components with efficiency and precision. Their dedication to quality and innovation has earned them a solid reputation in the industry, both domestically and internationally.The company's commitment to customer satisfaction and their ability to deliver customized solutions has been a key factor in their success. By working closely with their clients and understanding their specific needs, they have been able to develop tailor-made CNC turning parts that meet the highest standards of quality and precision. This has allowed them to build strong, long-term relationships with their customers and secure a strong position in the global market.The increasing demand for CNC turning parts in China can be attributed to the rise of various industries that require high-precision components. The automotive industry, in particular, has been a major driver of this growth, as the need for precision-engineered parts continues to increase with the advancement of vehicle technology. Additionally, the aerospace and medical industries have also been driving the demand for CNC turning parts, as these sectors require components that meet stringent quality and safety standards.With the rise of automation and Industry 4.0, the demand for CNC turning parts is expected to further increase as more industries adopt advanced manufacturing technologies. This presents a significant opportunity for Chinese companies like {} to further expand their capabilities and seize a larger share of the global market.As a leader in the industry, {} has been proactive in embracing digitalization and automation in their manufacturing processes. By investing in advanced CNC machines and adopting smart manufacturing solutions, they have been able to increase their productivity and efficiency while maintaining the highest standards of quality. This has allowed them to keep up with the growing demand for CNC turning parts and stay competitive in the global market.Looking ahead, the future of the CNC turning parts industry in China looks promising, with the continued advancement of technology and the increasing demand for high-precision components across various industries. Companies like {} are well-positioned to capitalize on these opportunities and continue to lead the way in the manufacturing of CNC turning parts.In conclusion, the rise of the CNC turning parts industry in China is a testament to the country's growing capabilities in precision manufacturing. With companies like {} leading the way in innovation and quality, China is set to play a significant role in the global supply of CNC turning parts for the foreseeable future.

Durable and Affordable Sheet Metal Automotive Parts for Cars and Trucks

The automotive industry is continuously evolving and advancing with new technologies and innovations. One crucial aspect of vehicle manufacturing is the use of sheet metal automotive parts. These parts are essential in providing strength, durability, and structural integrity to the vehicles we drive, and they play a vital role in ensuring the safety of motorists on the road.One company that has been at the forefront of producing high-quality sheet metal automotive parts is {Company name}. With over 30 years of experience in the industry, {Company name} has established itself as a reliable and trusted supplier of sheet metal parts to leading automotive manufacturers around the world. The company's dedication to excellence, precision engineering, and customer satisfaction has made it a preferred choice for automotive companies looking for top-quality sheet metal parts for their vehicles.{Company name} specializes in the production of a wide range of sheet metal automotive parts, including body panels, chassis components, engine parts, and structural elements. The company utilizes state-of-the-art manufacturing processes and cutting-edge technology to ensure that its products meet the highest standards of quality and performance. With a team of skilled engineers and technicians, {Company name} is able to design and produce custom sheet metal parts that are tailored to the specific requirements of its clients.In addition to its commitment to quality, {Company name} is also dedicated to sustainability and environmental responsibility. The company employs eco-friendly manufacturing practices and strives to minimize its environmental impact by reducing waste, conserving energy, and using recyclable materials. This commitment to sustainability has not only earned {Company name} a reputation as a responsible corporate citizen but has also made it an attractive partner for automotive companies that prioritize environmental stewardship.One of the key advantages of using sheet metal automotive parts from {Company name} is the exceptional strength and durability that they offer. The company's parts are designed to withstand the rigors of everyday use and are capable of withstanding the harsh conditions of the road, including extreme temperatures, corrosion, and impact. This reliability and longevity make {Company name}'s sheet metal parts an ideal choice for vehicle manufacturers looking to build vehicles that are safe, durable, and long-lasting.Furthermore, {Company name} is constantly investing in research and development to stay ahead of the curve in the automotive industry. The company is continuously exploring new materials, manufacturing techniques, and design innovations to improve the performance and efficiency of its sheet metal parts. By staying at the forefront of advancements in automotive technology, {Company name} is able to provide its clients with cutting-edge solutions that meet the evolving demands of the automotive market.As the automotive industry continues to embrace new technologies such as electric and autonomous vehicles, the demand for high-quality sheet metal automotive parts is only expected to grow. {Company name} is well-positioned to meet this demand with its proven track record of delivering top-notch sheet metal parts to some of the biggest names in the automotive industry. With its unwavering commitment to quality, innovation, and sustainability, {Company name} is poised to remain a leader in the production of sheet metal automotive parts for years to come.In conclusion, sheet metal automotive parts are an essential component of vehicle manufacturing, and {Company name} is a leading supplier of these parts to the automotive industry. With its dedication to quality, sustainability, and innovation, {Company name} is a trusted partner for automotive companies looking for top-quality sheet metal parts for their vehicles. As the automotive industry continues to evolve, {Company name} is well-equipped to meet the growing demand for high-performance sheet metal parts and to remain at the forefront of the industry.

How Injection Mold Pressure Impacts the Manufacturing Process

Injection Mold Pressure (name removed) has recently introduced a new line of high-pressure injection molds, revolutionizing the industry with their cutting-edge technology and unparalleled precision. With a focus on quality and innovation, Injection Mold Pressure (name removed) is setting new standards for injection molding and solidifying their position as a leader in the market.With over 20 years of experience in the industry, Injection Mold Pressure (name removed) has established a reputation for delivering top-of-the-line products and exceeding customer expectations. Their team of expert engineers and designers are committed to pushing the boundaries and staying ahead of the curve when it comes to injection mold technology.The new line of high-pressure injection molds from Injection Mold Pressure (name removed) is designed to meet the demands of a wide range of industries, including automotive, aerospace, healthcare, and consumer goods. These molds are engineered to withstand extreme pressure and temperature conditions, ensuring optimal performance and longevity.One of the key features of Injection Mold Pressure (name removed)’s high-pressure injection molds is their ability to produce complex and intricate parts with unmatched precision. This level of accuracy is critical for industries that require tight tolerances and flawless finishes, and Injection Mold Pressure (name removed) is committed to delivering on these requirements.In addition to their precision engineering, Injection Mold Pressure (name removed)’s high-pressure injection molds are also known for their efficiency and productivity. By optimizing the design and manufacturing process, these molds are able to produce high volumes of parts in a short amount of time, reducing lead times and increasing overall output.Furthermore, Injection Mold Pressure (name removed)’s high-pressure injection molds are built to last, with a focus on durability and reliability. This means that customers can trust in the longevity of their molds, minimizing downtime and maintenance costs in the long run.To support their new line of high-pressure injection molds, Injection Mold Pressure (name removed) has also invested in state-of-the-art manufacturing facilities and equipment. This allows them to maintain strict quality control measures and ensure that each mold meets their rigorous standards before it leaves the facility.With their commitment to excellence and continuous improvement, Injection Mold Pressure (name removed) is positioned to make a significant impact on the injection molding industry with their new line of high-pressure injection molds. Customers can expect to experience improved performance, increased productivity, and overall cost savings with these innovative products.In conclusion, Injection Mold Pressure (name removed)’s new line of high-pressure injection molds represents a significant advancement in injection mold technology. With their focus on precision, efficiency, and durability, these molds are poised to elevate the standards of the industry and provide customers with a competitive edge. Injection Mold Pressure (name removed) continues to lead the way in innovation and quality, solidifying their position as a trusted partner for all injection molding needs.

Top Tips for Custom Machined Metal Parts: Enhancing Precision and Efficiency

[Company Introduction]Custom Machined Metal Parts is a leading manufacturer and supplier of precision-engineered metal parts based in [Company Location]. With years of experience in the industry, we have earned a reputation for delivering high-quality products and exceptional customer service. Our state-of-the-art facilities, cutting-edge technologies, and skilled workforce enable us to cater to the diverse needs of clients across various industries. From prototype development to mass production, we specialize in manufacturing custom metal parts that meet the exact specifications and requirements of our clients.[News Content]Custom Machined Metal Parts Expands Production Capacity to Meet Growing Demand[City, Date] - Custom Machined Metal Parts, a renowned manufacturer and supplier of precision-engineered metal parts, has recently announced a significant expansion of its production capabilities to cater to the increasing demand from clients across different industries.As market demand for high-quality metal parts continues to surge, Custom Machined Metal Parts aims to ensure that it remains at the forefront of the industry by scaling up its operations. The expansion includes the installation of state-of-the-art machinery, the hiring of additional skilled personnel, and the optimization of production processes.The new machinery acquired by Custom Machined Metal Parts is equipped with advanced automation features and cutting-edge technologies, allowing for enhanced precision, efficiency, and speed. This modernization will significantly reduce production lead times and enable the company to better meet the ever-growing demands of its clients."Our decision to expand our production capacity is a strategic move to align with the market's rapid growth and to meet the increasing demands of our valued customers," said [Company Spokesperson]. "We are committed to maintaining our reputation of providing superior metal parts and exceptional service, and this expansion will enable us to do just that."This expansion will not only benefit Custom Machined Metal Parts but also its clients. By reducing lead times and increasing production capacity, the company will be able to accommodate orders of various sizes more efficiently. This will ensure that clients receive their custom-made metal parts promptly, enhancing their own operations and minimizing delays in their production cycles.Furthermore, Custom Machined Metal Parts is also focusing on the hiring and training of additional skilled personnel. This move aims to consolidate the company's technical expertise while creating job opportunities for local communities. By nurturing a skilled workforce, Custom Machined Metal Parts ensures that its products continue to meet and exceed the highest industry standards.With its expanded production capacity and continued emphasis on quality and innovation, Custom Machined Metal Parts is well-positioned to further solidify its position as a leader in the precision metal parts manufacturing industry. The company's commitment to exceptional customer service and its ability to adapt to changing market demands will continue to drive its growth and success.About Custom Machined Metal PartsCustom Machined Metal Parts is a leading manufacturer and supplier of precision-engineered metal parts. With a wide range of capabilities and a commitment to excellence, the company serves clients across various industries. From concept to delivery, Custom Machined Metal Parts delivers high-quality custom metal parts that meet the unique specifications and requirements of its customers.For more information, please contact:[Company Name][Contact Person][Phone][Email][Website]