High-Quality CNC Metal Machining Service for Your Business

By:Admin

With the increasing demand for precision metal parts in various industries, the need for reliable and efficient CNC metal machining services has never been higher. One company that has been meeting this demand is {}, a leading provider of CNC metal machining services. With a focus on quality, precision, and customer satisfaction, {} has established itself as a trusted partner for businesses in need of custom metal parts.

Founded in 2005, {} has over 15 years of experience in the industry. The company has built a reputation for delivering high-quality products that meet the specific needs of its customers. With a state-of-the-art facility and a team of skilled machinists, {} is able to handle a wide range of projects, from simple components to complex parts with tight tolerances.

One of the key factors that sets {} apart from other CNC machining services is its commitment to using the latest technology and techniques. The company invests in advanced CNC machines and inspection equipment to ensure that every product meets the highest standards of quality and accuracy. This dedication to technology also allows {} to stay ahead of the competition and provide its customers with the most innovative and cost-effective solutions.

In addition to its technological capabilities, {} places a strong emphasis on customer service. The company understands that every project is unique, and it works closely with its customers to understand their specific requirements and provide personalized solutions. By maintaining open communication and offering responsive support, {} aims to build long-term relationships with its clients and become their trusted partner for all their CNC metal machining needs.

One of the industries that {} serves is the aerospace sector, where precision and reliability are of utmost importance. With its expertise in CNC metal machining, the company is able to produce components that meet the strict standards and regulations of the aerospace industry. From engine parts to structural components, {} has the capabilities to deliver the high-quality products that aerospace manufacturers rely on.

Another sector that {} serves is the automotive industry, where the demand for custom metal parts is constantly growing. With its advanced CNC machining capabilities, the company is able to produce a wide range of components for automotive applications, including engine parts, transmission components, and suspension systems. By consistently delivering products that meet the stringent requirements of the automotive industry, {} has become a trusted supplier to leading manufacturers in the sector.

As the demand for custom metal parts continues to grow across various industries, {} remains committed to providing its customers with the highest quality products and services. By investing in technology, maintaining a focus on customer satisfaction, and staying ahead of industry trends, the company is well-positioned to meet the evolving needs of its clients and continue as a leader in the CNC metal machining industry. With its track record of excellence and dedication to innovation, {} is set to remain a reliable partner for businesses in need of precision metal parts for many years to come.

Company News & Blog

High-Quality Precision Machining Parts for Various Applications

Precision Machining Parts (PMP) is a leading manufacturer of high-quality precision machined components for a wide range of industries, including aerospace, automotive, medical, and electronics. With state-of-the-art facilities and a team of highly skilled engineers and technicians, PMP is known for its commitment to delivering superior products that meet the strictest quality standards.The company's manufacturing capabilities encompass a wide variety of materials, including aluminum, stainless steel, titanium, and plastics, allowing them to produce parts that meet the specific needs of their customers. From prototypes to high-volume production runs, PMP has the expertise and technology to handle a diverse array of projects with precision and efficiency.One of the key factors that set PMP apart from its competitors is its dedication to continuous improvement and innovation. The company regularly invests in the latest machining technology and equipment to ensure that they remain at the forefront of the industry. This commitment to staying ahead of the curve enables PMP to meet the evolving demands of its customers and consistently deliver cutting-edge solutions.In addition to its technical prowess, PMP prioritizes customer satisfaction by providing personalized service and support throughout the entire manufacturing process. From the initial consultation to the final delivery, the company's team works closely with each client to understand their unique requirements and ensure that the finished parts meet or exceed expectations.As part of its ongoing efforts to expand its capabilities and reach new markets, PMP recently announced the launch of several new product lines that leverage the latest advancements in precision machining technology. These products are designed to address the growing demand for complex, high-performance components across various industries, further solidifying PMP's position as a top-tier provider of precision machining solutions.One of the key highlights of PMP's new product offerings is a line of aerospace components that are engineered to meet the stringent requirements of the aerospace industry. Leveraging advanced materials and cutting-edge manufacturing techniques, these components are designed to deliver exceptional performance in the most demanding aerospace applications.Furthermore, PMP has also introduced a range of medical device components that are tailored to meet the exacting standards of the medical industry. With a focus on precision, reliability, and biocompatibility, these components are designed to support the development of innovative medical devices that improve patient care and outcomes.Additionally, PMP has expanded its range of automotive components to address the evolving needs of the automotive industry, including the growing demand for electric and hybrid vehicles. By leveraging its expertise in precision machining, the company is well-positioned to support the development of next-generation automotive technologies.In response to the increasing demand for electronics components with higher performance and miniaturization, PMP has also unveiled a new line of precision machined electronics components. These components are designed to meet the stringent tolerances and quality standards required by the electronics industry, enabling manufacturers to achieve optimal performance and reliability in their products.With these new product offerings, PMP is poised to further expand its presence in key industries and provide tailored solutions that address the specific needs of its customers. By combining its technical expertise, advanced manufacturing capabilities, and commitment to customer satisfaction, PMP is well-positioned to continue its growth trajectory and solidify its reputation as a trusted partner for precision machining solutions.As PMP continues to push the boundaries of what is possible in precision machining, the company remains focused on upholding its core values of quality, innovation, and customer-centricity. By staying true to these principles, PMP is well-equipped to navigate the evolving landscape of precision manufacturing and continue delivering exceptional value to its clients.

High-Quality Vacuum Casting Services in China for rapid prototyping and small batch production

Vacuum Casting China – Revolutionizing Manufacturing in the RegionIn the fast-paced world of manufacturing, the ability to produce high-quality prototypes and end-use parts in a cost-effective and timely manner is crucial for businesses to stay competitive. This is where Vacuum Casting China, a leading provider of rapid prototyping and low-volume production solutions, comes into play.With state-of-the-art facilities and a team of skilled technicians, Vacuum Casting China has been at the forefront of revolutionizing manufacturing in the region. Specializing in vacuum casting, a highly versatile and efficient manufacturing process, the company has earned a reputation for delivering precision-engineered components to a wide range of industries, including automotive, aerospace, consumer goods, and more. Their commitment to excellence and innovation has positioned them as a trusted partner for businesses seeking to bring their ideas to life.One of the key advantages of vacuum casting is its ability to produce high-quality prototypes and end-use parts with the look and feel of production-grade materials. This makes it an ideal solution for product development, allowing businesses to test and iterate their designs before moving to mass production. Vacuum Casting China’s advanced technology and expertise enable them to deliver parts that meet the required functional and aesthetic standards, giving their clients the confidence to move forward with their projects.Furthermore, vacuum casting is well-suited for low-volume production, providing a cost-effective alternative to traditional manufacturing methods such as injection molding. This makes it an attractive option for businesses looking to produce small to medium quantities of parts without the high upfront costs and long lead times typically associated with mass production. Vacuum Casting China’s streamlined process and quick turnaround times enable their clients to bring products to market faster, giving them a competitive edge in their respective industries.In addition to their technical capabilities, Vacuum Casting China prides itself on its commitment to customer satisfaction. Their team of experts works closely with clients throughout every stage of the manufacturing process, from design and material selection to production and delivery. This collaborative approach ensures that each project is tailored to the specific needs and requirements of the client, resulting in a finished product that exceeds expectations.With a focus on quality, precision, and efficiency, Vacuum Casting China has established itself as a leader in the industry, earning the trust and loyalty of businesses both locally and internationally. Their cutting-edge technology, combined with their passion for innovation, has enabled them to deliver superior solutions that drive the success of their clients.As the manufacturing landscape continues to evolve, Vacuum Casting China remains committed to staying ahead of the curve. By investing in research and development, expanding their capabilities, and fostering partnerships with leading businesses, they are poised to continue revolutionizing manufacturing in the region and beyond.In conclusion, Vacuum Casting China’s dedication to excellence, coupled with their advanced technology and customer-centric approach, has positioned them as a driving force in the manufacturing industry. With their ability to deliver high-quality prototypes and end-use parts in a timely and cost-effective manner, they are paving the way for businesses to thrive in today’s competitive market. As they continue to innovate and expand their reach, Vacuum Casting China is set to shape the future of manufacturing for years to come.

Advanced 3D CNC Machining: Everything You Need to Know

3D CNC Machining is Revolutionizing Manufacturing IndustryIn today's fast-paced manufacturing industry, the demand for precision and high-quality products is at an all-time high. With the advancement of technology, the introduction of 3D CNC machining has revolutionized the way products are designed and manufactured. This cutting-edge technology has enabled manufacturers to produce intricate and complex parts with incredibly tight tolerances, leading to superior end products.One company at the forefront of 3D CNC machining is {}. With a long-standing reputation for excellence in precision manufacturing, the company has fully embraced this innovative technology to meet the evolving needs of their diverse client base. Equipped with state-of-the-art CNC machines and a team of highly skilled engineers and technicians, they have set a new standard for precision manufacturing.The process of 3D CNC machining involves the use of computer-aided design (CAD) software to create a digital model of the desired part. This model is then translated into a set of instructions for the CNC machine, which uses advanced cutting tools to precisely carve the part from a solid block of material. The result is a flawless replication of the original design, with unmatched accuracy and repeatability.One of the key advantages of 3D CNC machining is its ability to produce highly complex parts that would be impossible to manufacture using traditional methods. The precision and flexibility of CNC machines allow for the creation of intricate geometries and fine details, making it ideal for industries such as aerospace, medical, automotive, and defense, where the need for precision is paramount.Furthermore, 3D CNC machining offers significant time and cost savings compared to traditional manufacturing processes. With the ability to rapidly prototype and produce parts with minimal setup and lead times, manufacturers can bring their products to market faster and more competitively. This has led to increased productivity and efficiency for companies embracing this cutting-edge technology.With its commitment to innovation and excellence, {} has invested in the latest CNC machining technology to ensure that they stay ahead of the curve. By leveraging the capabilities of 3D CNC machining, they have been able to expand their capabilities in creating intricate and high-precision parts for a wide range of industries. Their dedication to delivering top-quality products has solidified their position as a leader in the precision manufacturing industry.In addition to its impact on manufacturing, 3D CNC machining has also opened up new possibilities for product design and customization. The ability to quickly iterate and fine-tune designs has empowered engineers and designers to push the boundaries of what is possible, leading to the development of innovative and groundbreaking products.As the manufacturing industry continues to evolve, the adoption of 3D CNC machining is expected to grow exponentially. Its ability to produce high-precision, complex parts with unmatched speed and efficiency has made it an indispensable tool for manufacturers looking to stay competitive in today's fast-paced market.With its proven track record and commitment to excellence, {} is well-positioned to continue leading the way in the adoption and advancement of 3D CNC machining. By harnessing the power of this revolutionary technology, they are poised to meet the ever-changing needs of their clients and drive the future of precision manufacturing.

The Essential Guide to Die Casting Plastic: Everything You Need to Know

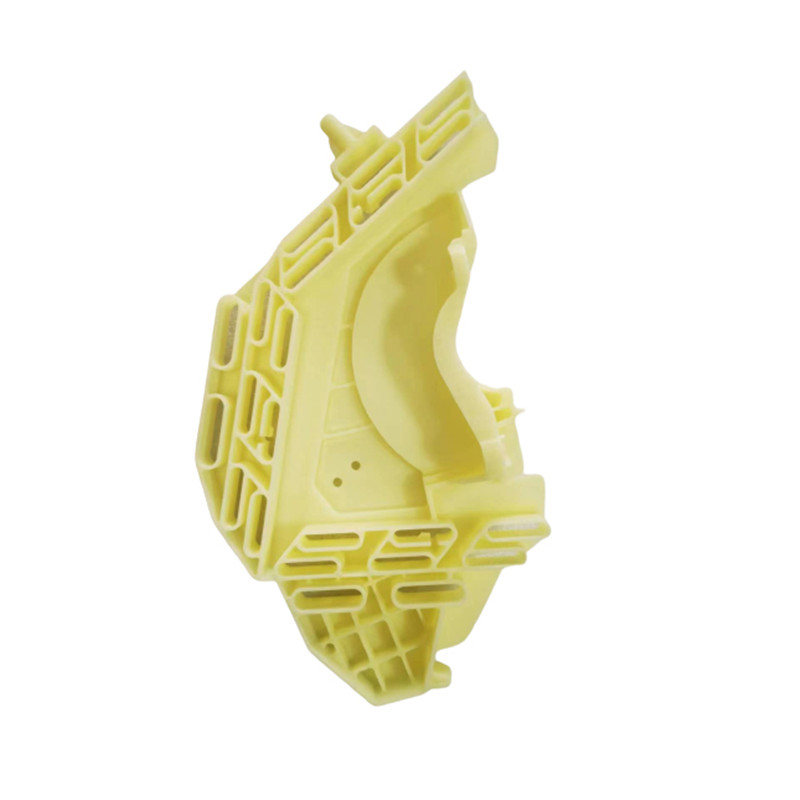

Die Casting Plastic has recently announced a new partnership with a major automobile manufacturing company, marking a significant milestone for the company and representing a major breakthrough in the automotive industry. This new collaboration will see Die Casting Plastic provide advanced plastic die casting solutions for the development of the next generation of electric vehicles.Founded in {year}, Die Casting Plastic has established itself as a leader in the die casting industry, specializing in the production of high-quality plastic components for a wide range of applications. The company's commitment to innovation and continuous improvement has earned it a strong reputation for delivering cutting-edge solutions that meet the evolving needs of its customers.In recent years, the automotive industry has been undergoing a significant transformation, with a growing emphasis on electric vehicles that are more environmentally friendly and sustainable. As a result, there is an increasing demand for advanced technologies and materials that can support the production of electric vehicles that are both high-performing and cost-effective.The partnership between Die Casting Plastic and the automobile manufacturing company represents a strategic move to address this demand by leveraging Die Casting Plastic's expertise in plastic die casting to develop innovative solutions for electric vehicle components. By combining their resources and capabilities, the two companies aim to accelerate the development and production of electric vehicles, contributing to the ongoing shift towards a greener and more sustainable automotive industry.Through this collaboration, Die Casting Plastic will apply its extensive knowledge and experience in plastic die casting to support the development of a wide range of components for electric vehicles, including battery enclosures, powertrain components, and structural parts. These components will be designed to meet the highest standards of quality, performance, and durability, while also contributing to the overall lightweighting and efficiency of electric vehicles.The CEO of Die Casting Plastic expressed enthusiasm about the partnership, highlighting the company's commitment to driving innovation and making a meaningful impact on the automotive industry. He stated, "We are thrilled to be collaborating with {automobile manufacturing company} to advance the development of electric vehicles. This partnership is a testament to our dedication to pushing the boundaries of what is possible in plastic die casting and supporting the transition towards a more sustainable transportation industry."In addition to its contributions to electric vehicle development, Die Casting Plastic is also known for its broader efforts to promote sustainability and environmental responsibility in its operations. The company has implemented various initiatives to minimize its environmental footprint, including the adoption of eco-friendly manufacturing processes, the use of recycled materials, and the development of energy-efficient production technologies.As part of its dedication to sustainability, Die Casting Plastic is committed to ensuring that its products and solutions align with the principles of environmental consciousness and contribute to the overall reduction of carbon emissions in the automotive sector. This aligns with the broader mission of the company to drive positive change and make a meaningful impact on the world.The partnership between Die Casting Plastic and the automobile manufacturing company represents a significant step forward in the quest to accelerate the development and adoption of electric vehicles. By leveraging Die Casting Plastic's expertise in plastic die casting and the automotive company's industry-leading position, the collaboration is poised to drive innovation, efficiency, and sustainability in the automotive industry. As electric vehicles continue to gain momentum, partnerships such as this will play a crucial role in shaping the future of transportation and creating a more sustainable world for generations to come.

Precision Machining Services for Aluminum Parts

[Company Name], a leading manufacturer of precision machining parts, has been making waves in the industry with its superior quality aluminum parts. The company has gained a reputation for excellence in precision machining and has become the go-to choice for businesses seeking top-of-the-line aluminum parts.The demand for aluminum parts has been steadily increasing in multiple industries, including aerospace, automotive, and medical equipment manufacturing. Aluminum is known for its durability, strength, and lightweight properties, making it an excellent choice for many applications. As such, the precision machining of aluminum parts is crucial in ensuring the quality and reliability of the end products.With cutting-edge technology and a team of highly skilled machinists, [Company Name] has established itself as a leader in the precision machining industry. The company's state-of-the-art facilities are equipped with the latest CNC machines and other precision tools, allowing them to produce aluminum parts with unparalleled accuracy and precision.One of the key strengths of [Company Name] is its ability to work with a wide range of aluminum alloys. Whether it's 6061, 7075, or a specialized alloy, the company has the expertise to machine aluminum parts to meet the most stringent specifications. This flexibility has made [Company Name] a preferred partner for businesses with diverse machining needs.Furthermore, the company's commitment to quality is evident in its rigorous quality control processes. Every aluminum part produced by [Company Name] undergoes thorough inspection to ensure compliance with industry standards and customer requirements. This dedication to quality has earned the company certifications and accolades, further solidifying its position as a trusted precision machining partner.In addition to its superior machining capabilities, [Company Name] takes pride in its customer-centric approach. The company works closely with clients to understand their unique needs and provide tailored solutions that meet or exceed their expectations. This personalized service has helped [Company Name] build long-lasting relationships with a wide range of businesses, from small enterprises to multinational corporations.Moreover, [Company Name] understands the importance of timely delivery. The company has implemented efficient production processes and optimized its supply chain to ensure that customers receive their aluminum parts on time, every time. This reliability has made [Company Name] a preferred supplier for businesses with strict production schedules and deadlines.Looking ahead, [Company Name] is poised to further expand its capabilities in machining aluminum parts. The company continues to invest in cutting-edge technology and talent, with the goal of pushing the boundaries of precision machining. Additionally, [Company Name] is committed to staying at the forefront of industry trends and advancements, so it can continue to deliver innovative solutions to its customers.In conclusion, [Company Name] has established itself as a trusted and reliable partner for precision machining aluminum parts. With its advanced technology, skilled workforce, and dedication to quality and customer satisfaction, the company is well-positioned to meet the growing demand for high-quality aluminum parts in various industries. As [Company Name] continues to innovate and expand its capabilities, it is set to maintain its leadership in the precision machining industry.

High-Quality Aluminum Casting Parts for Various Applications

Aluminum Casting Parts: A Step Towards Innovation and ExcellenceIn today's competitive and constantly evolving world, precision and reliability are paramount in manufacturing. As industries continue to grow and expand, the demand for high-quality and durable components has surged. This is where aluminum casting parts have emerged as a game-changer, offering a wide range of applications in various industries. These parts are known for their precision, strength, and versatility, making them a popular choice for manufacturers across different sectors.One company that stands out in the production of aluminum casting parts is {}. With a focus on innovation and excellence, the company has carved a niche for itself in the manufacturing industry. Their commitment to quality and customer satisfaction has earned them a reputation as a trusted and reliable supplier of aluminum casting parts.Established in {}, {} has continuously evolved and adapted to meet the changing needs of the industry. With state-of-the-art facilities and a team of experienced professionals, the company has become a leading supplier of aluminum casting parts. Their ability to cater to the diverse requirements of clients has set them apart as a preferred choice for businesses seeking high-quality components.One of the key advantages of aluminum casting parts lies in their versatility. These parts can be used in a wide range of applications, including automotive, aerospace, marine, and industrial machinery. Their ability to withstand high temperatures and corrosive environments makes them ideal for challenging operating conditions. Additionally, aluminum casting parts are lightweight, yet incredibly strong, offering an excellent strength-to-weight ratio that is essential for many applications.The manufacturing process at {} involves the use of advanced technology and stringent quality control measures. This ensures that the aluminum casting parts produced are not only precise and reliable but also meet the highest industry standards. The company's dedication to continuous improvement and investment in cutting-edge technologies has enabled them to stay ahead of the competition and deliver superior products to their clients.The team at {} is committed to providing tailored solutions to their clients, understanding their unique requirements and delivering products that meet their specific needs. Whether it is a complex design or a large-scale production run, the company has the capabilities and resources to fulfill the most demanding projects. Their efficient production processes and streamlined operations enable them to deliver high-quality aluminum casting parts in a timely manner, giving their clients a competitive edge in their respective industries.In addition to their commitment to quality, {} also places a strong emphasis on environmental sustainability. The company adheres to strict environmental regulations and employs eco-friendly manufacturing practices, minimizing their carbon footprint and contributing to a greener future. By prioritizing sustainability, {} demonstrates their dedication to being a responsible and ethical corporate citizen.Looking ahead, {} remains focused on driving innovation and pushing the boundaries of what is possible in the manufacturing industry. With a forward-thinking approach and a passion for excellence, the company is well-positioned to continue its success and make a lasting impact in the world of aluminum casting parts.As the demand for high-quality, reliable components continues to grow, the significance of aluminum casting parts will only continue to increase. With {} at the forefront of this industry, businesses can expect access to superior aluminum casting parts that meet their technical specifications and performance requirements. As {} continues to innovate and expand its capabilities, the company is poised to set new benchmarks for excellence in the manufacturing of aluminum casting parts.

Quality Injection Mould Manufacturing: The Ultimate Guide

Injection Mould Manufacturing, a leading company in the field of plastic injection molding, has been making waves in the industry with its cutting-edge technology and high-quality products. The company, which was established in 1998, has since become a trusted name in the world of plastic injection molding, catering to a wide range of industries such as automotive, medical, and consumer goods.With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, Injection Mould Manufacturing has the capability to design and produce custom molds to meet the unique requirements of its clients. Whether it's a small-scale prototype or a large-scale production run, the company is able to deliver high-precision molds with quick turnaround times.One of the key factors that sets Injection Mould Manufacturing apart from its competitors is its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly exploring new materials and manufacturing techniques to stay ahead of the curve. This forward-thinking approach has enabled Injection Mould Manufacturing to adapt to the ever-changing demands of the industry and provide its customers with the most advanced solutions available.In addition to its technical prowess, Injection Mould Manufacturing places a strong emphasis on quality control and customer satisfaction. The company adheres to strict quality standards and has implemented rigorous inspections at every stage of the manufacturing process to ensure that the final product meets the highest levels of excellence. Moreover, Injection Mould Manufacturing prides itself on its ability to work closely with its clients, offering personalized service and support to address their specific needs and concerns.Furthermore, Injection Mould Manufacturing has recently expanded its production capacity to meet the growing demand for its products. The company has invested in new equipment and machinery, as well as expanded its workforce, to ensure that it is well-equipped to handle larger and more complex projects. This expansion reflects Injection Mould Manufacturing's commitment to staying at the forefront of the industry and its dedication to delivering top-notch solutions to its customers.In line with its efforts to stay at the forefront of the industry, Injection Mould Manufacturing has also been actively involved in sustainability initiatives. The company has taken steps to minimize its environmental footprint by adopting eco-friendly manufacturing processes and reducing waste. Injection Mould Manufacturing recognizes the importance of environmental responsibility and aims to be a leader in sustainable manufacturing practices.As Injection Mould Manufacturing continues to grow and evolve, its dedication to excellence and innovation remains unwavering. The company's relentless pursuit of quality, coupled with its adaptability and customer-centric approach, positions it as a formidable player in the plastic injection molding industry. With a solid track record of delivering exceptional results, Injection Mould Manufacturing is well-positioned to meet the evolving needs of its clients and drive the industry forward.

Different Types of Injection Molds: A Comprehensive Guide

Injection Mold Types to Revolutionize Manufacturing Process: A Breakthrough from [Company Name][Company Name] is proud to present a groundbreaking innovation in the field of manufacturing. The injection mold types developed by [Company Name] are set to revolutionize the way products are produced, offering a level of precision and efficiency previously unattainable.Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. It is commonly used for manufacturing a variety of products, ranging from small components to large objects. The process is ideal for producing high volumes of components and is widely used in industries such as automotive, consumer goods, medical devices, and aerospace.[Company Name] has spent years researching and developing injection mold types that address the limitations of traditional molds. The result is a range of injection mold types that offer unparalleled precision, speed, and versatility.One of the key features of [Company Name]'s injection mold types is their ability to produce complex geometries with high precision. Traditional molds often struggle to produce parts with intricate designs, leading to compromises in the final product's quality. However, [Company Name]'s injection mold types are capable of producing parts with intricate details and tight tolerances, ensuring that the final products meet the highest standards of quality.Moreover, [Company Name]'s injection mold types are designed to increase production efficiency. By optimizing the mold design and manufacturing process, [Company Name] has achieved significant reductions in cycle times, resulting in faster production rates and lower costs. This not only benefits manufacturers by increasing their operational efficiency but also allows them to meet tight production deadlines and respond quickly to changing market demands.In addition, [Company Name]'s injection mold types offer a greater degree of flexibility in material choices. This means that manufacturers can use a wide range of materials with varying properties, allowing them to produce parts with specific mechanical, thermal, or chemical characteristics. This flexibility is particularly beneficial for industries where the performance of the final product is crucial, such as automotive and aerospace.Furthermore, [Company Name]'s injection mold types are engineered for durability and longevity. The materials and manufacturing processes used in their construction ensure that the molds can withstand the high pressures and temperatures involved in the injection molding process. This results in reduced mold maintenance and replacement costs, providing manufacturers with long-term savings and peace of mind.According to [Company Name]'s CEO, [CEO Name], "Our injection mold types represent a significant leap forward in manufacturing technology. We believe that our innovative approach will redefine the standards of injection molding and empower manufacturers to achieve new levels of quality, efficiency, and competitiveness."[Company Name] has already received overwhelming interest from leading manufacturers across various industries. The company's injection mold types have been praised for their potential to transform manufacturing processes and drive innovation in product development.In addition to its injection mold types, [Company Name] offers a range of services to support manufacturers in implementing the new technology. These include mold design and engineering, prototyping, and technical support to ensure a seamless integration of the injection mold types into the manufacturing process.The introduction of [Company Name]'s injection mold types marks a significant milestone in the evolution of manufacturing technology. With their ability to produce high-precision parts, increase production efficiency, and offer flexibility in material choices, [Company Name]'s injection mold types are set to revolutionize the manufacturing industry and open up new opportunities for product innovation and development. As the adoption of these injection mold types continues to grow, [Company Name] is poised to lead the way in advancing the capabilities of injection molding and shaping the future of manufacturing.

The Best Material for Plastic Moulds: A Complete Guide

Plastic Mould Material, a leading provider of high-quality plastic mold materials, has been making waves in the manufacturing industry. With a strong commitment to innovation and excellence, the company has become a trusted name in the field of plastic mold materials.Since its inception, Plastic Mould Material has been dedicated to delivering top-notch products that meet the needs of its customers. The company's extensive range of plastic mold materials is designed to cater to a wide variety of applications, from automotive and aerospace to medical and consumer goods.One of the key factors that set Plastic Mould Material apart from its competitors is its commitment to quality. The company uses only the finest materials and employs the latest manufacturing techniques to ensure that its products are of the highest standard. This dedication to quality has earned Plastic Mould Material a reputation for excellence and reliability in the industry.In addition to its focus on quality, Plastic Mould Material is also known for its innovative approach to product development. The company continuously invests in research and development to stay ahead of the curve and provide its customers with cutting-edge solutions. By keeping a finger on the pulse of the industry, Plastic Mould Material is able to anticipate market trends and develop products that meet the evolving needs of its customers.Furthermore, Plastic Mould Material has a strong commitment to sustainability and environmental responsibility. The company is dedicated to reducing its environmental impact and operates with a focus on sustainability throughout its manufacturing processes. By implementing a range of eco-friendly practices, such as energy-efficient manufacturing and waste reduction initiatives, Plastic Mould Material strives to minimize its carbon footprint and contribute to a greener future.With a global presence, Plastic Mould Material serves a diverse customer base, providing its products to manufacturers around the world. The company's international reach has allowed it to establish strong partnerships with industry leaders and build a reputation for reliability and consistency in delivering high-quality plastic mold materials.Looking ahead, Plastic Mould Material is poised for continued growth and success in the industry. The company's unwavering commitment to excellence, innovation, and sustainability sets it apart as a leader in the field of plastic mold materials. As it continues to expand its product offerings and reach new markets, Plastic Mould Material is well-positioned to maintain its position as a trusted partner for manufacturers seeking top-quality plastic mold materials.In conclusion, Plastic Mould Material has earned its reputation as a leading provider of high-quality plastic mold materials through its focus on quality, innovation, and sustainability. With a global presence and a commitment to customer satisfaction, the company is well-positioned for continued success in the industry. For manufacturers seeking reliable and cutting-edge plastic mold materials, Plastic Mould Material is the partner of choice.

High-Quality CNC Components: An Essential Guide for Manufacturers

CNC Components: Revolutionizing the Manufacturing IndustryIn the realm of manufacturing, precision plays a pivotal role in the production process. Every tiny detail and intricacy needs to be accurately cut and molded to ensure a flawless end product. This is where CNC components come into play, revolutionizing the manufacturing industry with their unparalleled precision and efficiency.(CNC Components) has been at the forefront of this revolution, providing cutting-edge CNC components that have redefined the standards of precision and accuracy in manufacturing. With their state-of-the-art technology and unwavering commitment to quality, (CNC Components) has managed to carve a niche for themselves in the highly competitive world of manufacturing.Established with the vision of transforming the manufacturing industry, (CNC Components) has continuously strived to push the boundaries of innovation and excellence. Their extensive range of CNC components caters to a diverse array of industries, including automotive, aerospace, medical, and more. Whether it's intricate and complex parts or high-volume production, (CNC Components) has the capabilities to deliver exceptional results, time and time again.One of the key factors that set (CNC Components) apart from the competition is their unwavering commitment to quality. Each CNC component undergoes rigorous testing and quality control measures to ensure that it meets the highest standards of precision and accuracy. This dedication to perfection has earned (CNC Components) a stellar reputation for reliability and consistency in the manufacturing industry.Furthermore, (CNC Components) places a strong emphasis on innovation and technological advancement. They are constantly investing in research and development to stay ahead of the curve and introduce cutting-edge solutions to the market. This relentless pursuit of innovation has enabled (CNC Components) to stay at the forefront of the industry, offering revolutionary CNC components that redefine what is possible in the world of manufacturing.In addition to their tech-savvy approach, (CNC Components) also places a strong focus on customer satisfaction. They work closely with their clients to understand their specific needs and requirements, providing tailor-made solutions that exceed expectations. This customer-centric approach has cemented (CNC Components)'s position as a trusted partner for businesses looking to elevate their manufacturing capabilities.As the manufacturing industry continues to evolve and demand for precision and efficiency rises, the role of CNC components becomes increasingly crucial. (CNC Components) is well-positioned to meet these demands with their cutting-edge technology, unwavering commitment to quality, and customer-centric approach. With a strong track record of delivering exceptional results, it is no wonder that (CNC Components) is regarded as a leader in the world of CNC components.Looking ahead, (CNC Components) remains dedicated to pushing the boundaries of innovation and excellence in the manufacturing industry. Their relentless pursuit of perfection and commitment to customer satisfaction will continue to drive their success and reaffirm their position as a trailblazer in the world of CNC components.In conclusion, (CNC Components) has undoubtedly redefined the standards of precision and accuracy in the manufacturing industry. With their unwavering commitment to quality, cutting-edge technology, and customer-centric approach, they have solidified their position as a leader in CNC components. As the demand for precision and efficiency continues to soar, (CNC Components) stands poised to lead the charge and revolutionize the manufacturing industry for years to come.