High-Quality Custom CNC Machined Parts for Your Business

By:Admin

{} is a leading provider of custom CNC machined parts, offering a wide range of services to meet the needs of their diverse customer base. With state-of-the-art equipment and a team of highly skilled engineers and machinists, {} has established a reputation for delivering high-quality custom parts with quick turnaround times.

The company's CNC machining capabilities are truly impressive, with the ability to produce parts with complex geometries and tight tolerances. Whether clients require parts for aerospace, automotive, medical, or any other industry, {} has the expertise and technology to bring their designs to life.

In addition to their CNC machining services, {} also offers a range of secondary operations such as heat treating, anodizing, and assembly to provide their clients with a comprehensive manufacturing solution. With a focus on quality and customer satisfaction, {} is dedicated to being a one-stop shop for all of their clients' machining needs.

One of the key advantages of choosing {} for custom CNC machined parts is their commitment to utilizing the latest technology and software. By investing in the most advanced CNC machines and CAD/CAM software, {} is able to optimize their manufacturing processes and produce parts with unmatched precision and efficiency.

Furthermore, {} is dedicated to continuous improvement and innovation in their manufacturing processes. They regularly invest in new equipment and technologies to stay ahead of the curve and provide their clients with the best possible solutions for their custom machining needs.

With their wealth of experience and expertise in CNC machining, {} has developed a reputation for being a reliable and trusted partner for companies seeking high-quality custom parts. Their ability to handle complex projects and deliver results that exceed their clients' expectations has set them apart in the industry.

The success of {} can be attributed to their commitment to quality, precision, and customer satisfaction. By consistently delivering exceptional results and building strong relationships with their clients, {} has become a go-to source for custom CNC machined parts.

In conclusion, the demand for custom CNC machined parts continues to grow as companies seek to leverage the capabilities of advanced manufacturing technologies. With their extensive experience, cutting-edge equipment, and dedication to excellence, {} is well-positioned to meet the needs of their clients and drive innovation in the industry. Whether it's a prototype, a small production run, or a large-scale project, {} has the expertise and capabilities to deliver custom CNC machined parts that meet the highest standards of quality and precision.

Company News & Blog

Top CNC Supplier Offers High-Quality Machinery and Parts for Industries

[Your Name][Publication Name][Date]Title: Global CNC Supplier Revolutionizes Precision Engineering with Advanced TechnologiesSubtitle: [Company Name] Empowering Industrial Manufacturers with Cutting-Edge SolutionsIntroduction:[date] - The global manufacturing industry, driven by the perpetual need for precision, efficiency, and cost-effectiveness, has witnessed the emergence of innovative solutions that have transformed traditional production processes. Among the frontrunners in this transformation is [Company Name], a leading provider of advanced CNC (Computer Numerical Control) solutions. With a commitment to delivering cutting-edge technologies, [Company Name] has revolutionized the field of precision engineering, enabling businesses to enhance productivity, accuracy, and competitiveness.Body:1. Introduction to [Company Name]:[Company Name], established in [year], specializes in the provision of state-of-the-art CNC machinery and accessories, holding a strong position as a global supplier in the precision engineering market. With a focus on research and development, their team of experts continuously strives to push the boundaries of CNC technology, ensuring the delivery of high-quality, customizable solutions to meet the diverse needs of their worldwide clientele.2. Advanced CNC Solutions for Optimal Precision:Employing advanced technologies, [Company Name] offers an extensive range of CNC machines that cater to various industries such as aerospace, automotive, electronics, and medical devices. Whether it's milling, grinding, turning, or multitasking applications, their cutting-edge solutions provide exceptional accuracy and repeatability, allowing manufacturers to achieve intricate designs and complex geometries with ease.3. Integration of Smart Manufacturing Technologies:Recognizing the importance of smart manufacturing in the industry's digital transformation, [Company Name] has made substantial investments in integrating Internet of Things (IoT) capabilities into their CNC machinery. Through IoT connectivity, their machines collect real-time data, enabling manufacturers to monitor performance, track production metrics, and make data-driven decisions. This integration optimizes production efficiency, reduces downtime, and enhances overall operational productivity, granting manufacturers a competitive edge.4. Emphasizing Quality Control and Automation:In an effort to streamline manufacturing processes and enhance product quality, [Company Name] has incorporated advanced automation features into their CNC systems. This includes adaptive control systems, robotics, and artificial intelligence, ensuring consistency, reducing human error, and eliminating repetitive tasks. By automating various processes, manufacturers can achieve higher productivity, improved cycle times, and unparalleled precision, fostering better overall product quality.5. Commitment to Customer Satisfaction and Support:Aside from providing cutting-edge technology, [Company Name] places great emphasis on customer satisfaction and support. Their commitment extends beyond product delivery, as their team of experts offers comprehensive training programs, technical consultations, and exceptional after-sales support. By understanding their customers' unique requirements, [Company Name] ensures every client receives tailored solutions that result in optimized efficiency and profitability.6. Global Reach and Partnerships:With established distributors and partnerships across the globe, [Company Name] has successfully served clients in over [number] countries. Their expansive network ensures efficient customer service, prompt delivery, and localized support. By building enduring partnerships with industry leaders, the company remains well-positioned to address emerging trends and challenges in the fast-paced world of precision engineering.Conclusion:[Company Name] continues to transform the precision engineering industry, empowering manufacturers with the latest CNC technologies and innovative solutions backed by exceptional customer support. Through the integration of advanced automation, IoT capabilities, and a dedicated focus on precision, [Company Name] is enabling industrial businesses across the globe to achieve higher levels of productivity, cost-effectiveness, and competitiveness. In an ever-evolving manufacturing landscape, [Company Name] remains at the forefront, driving the industry forward with cutting-edge CNC solutions.

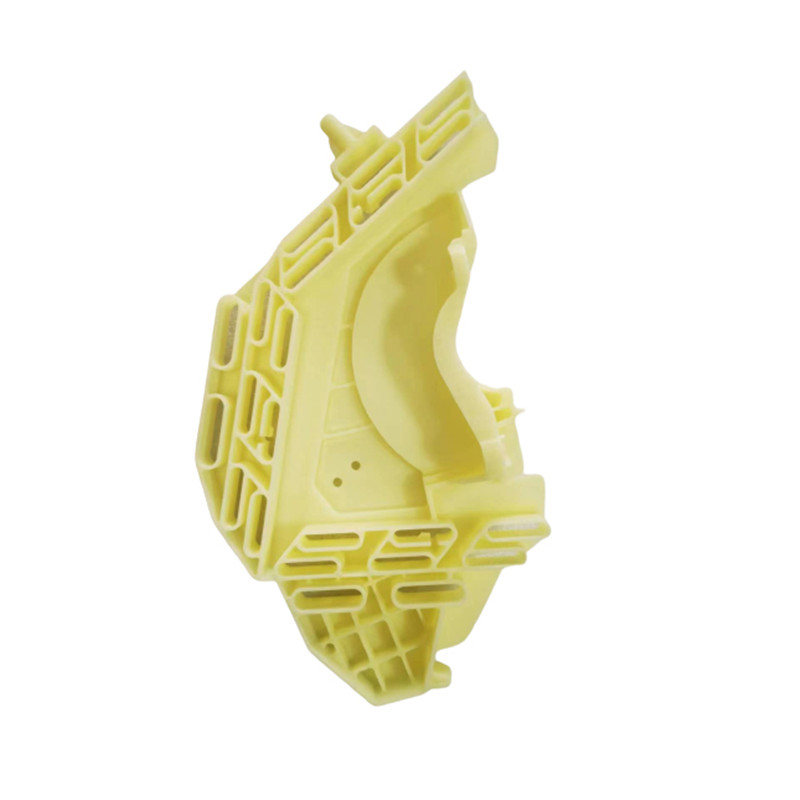

Custom Plastic Parts Machining Services for Various Industries

[Company Name] specializes in precision CNC machining for a wide range of industries, including aerospace, automotive, medical, and electronics. With a state-of-the-art facility and a team of highly skilled engineers and technicians, the company is able to provide high-quality, custom plastic parts that meet the exact specifications of their customers.Recently, [Company Name] has announced a new service for CNC machining plastic parts, expanding their capabilities to better serve the needs of their clients. The company has invested in advanced CNC machining technology specifically designed for producing complex plastic components with unmatched precision and accuracy. This new service is poised to meet the growing demand for high-quality plastic parts in various industries.CNC machining of plastic parts offers numerous advantages over traditional manufacturing methods. The process allows for the creation of intricate shapes and designs with tight tolerances, ensuring that the final product meets the exact requirements of the customer. Additionally, CNC machining produces parts with a high degree of consistency and repeatability, resulting in a more reliable and efficient manufacturing process.One of the key advantages of CNC machining plastic parts is the wide range of materials that can be used. [Company Name] has the capability to machine a variety of plastic materials, including ABS, acrylic, polycarbonate, and nylon, among others. This versatility allows the company to provide solutions for a diverse set of applications, from prototyping and low-volume production to full-scale manufacturing.The company’s team of engineers and technicians are highly experienced in working with plastic materials, ensuring that the machined parts meet the highest quality standards. Their expertise allows them to optimize the machining process for each specific material, maximizing efficiency and minimizing waste. This level of precision and attention to detail sets [Company Name] apart as a leader in the CNC machining industry.[Company Name] is committed to providing exceptional customer service and support throughout the entire manufacturing process. From initial design and engineering to final inspection and delivery, the company works closely with their clients to ensure that the finished plastic parts meet their exact specifications. This dedication to customer satisfaction has earned [Company Name] a reputation for reliability and excellence in the industry.The expanded CNC machining service for plastic parts is a significant milestone for [Company Name], further strengthening their position as a premier provider of precision machining solutions. By offering this new capability, the company is well-positioned to meet the evolving needs of their customers and provide innovative solutions for a wide range of applications. Whether it’s a complex prototype or a large-scale production run, [Company Name] has the expertise and technology to deliver superior plastic parts with unmatched precision and quality.In conclusion, [Company Name] is at the forefront of the CNC machining industry, providing advanced solutions for custom plastic parts. The company’s investment in state-of-the-art technology and their commitment to customer satisfaction make them a trusted partner for clients in a variety of industries. With their new CNC machining service for plastic parts, [Company Name] is poised to continue delivering exceptional results and driving innovation in the manufacturing sector.

Reliable FDM Printing Services Available Nearby

FDM Printing Companies Near Me: A Closer Look at {Company}The world of 3D printing has been rapidly expanding in recent years, and FDM (Fused Deposition Modeling) printing is one of the most popular methods of creating 3D printed objects. For those looking for FDM printing companies near me, there are a range of options to choose from. One such company is {Company}, which has established itself as a leader in the 3D printing industry.{Company} is known for its high-quality FDM printing services, offering a wide range of materials and technologies to meet the needs of its clients. With a state-of-the-art facility located in {Location}, {Company} is able to produce 3D printed parts and prototypes with precision and efficiency.The company's team of experts is equipped with extensive knowledge and experience in FDM printing, and they are dedicated to providing top-notch customer service. Whether it's a small prototype or a large-scale production run, {Company} is committed to delivering superior results for its clients.In addition to its FDM printing services, {Company} also offers a range of other 3D printing solutions, including SLA (Stereolithography) and SLS (Selective Laser Sintering). This diverse set of capabilities allows the company to cater to a wide variety of industries and applications, from aerospace and automotive to medical and consumer goods.Furthermore, {Company} is dedicated to staying at the forefront of technological advancements in the 3D printing industry. The company regularly invests in the latest equipment and software to ensure that it can offer the most cutting-edge solutions to its clients.As part of its commitment to sustainability, {Company} also prioritizes the use of eco-friendly materials and processes in its operations. This emphasis on environmental responsibility sets {Company} apart as a forward-thinking and socially conscious 3D printing company.{Company}'s dedication to quality, innovation, and customer satisfaction has earned it a strong reputation in the industry. Clients who choose {Company} for their FDM printing needs can expect exceptional results and a seamless, collaborative experience from start to finish.In addition to its technical expertise, {Company} also places a high value on building strong relationships with its clients. The company takes the time to understand each client's unique needs and goals, and works closely with them to deliver customized solutions that meet and exceed their expectations.As a result of its unwavering commitment to excellence, {Company} has attracted a diverse and loyal client base that includes both small startups and Fortune 500 companies. Whether it's a one-time project or an ongoing partnership, {Company} is dedicated to delivering exceptional results and building lasting relationships with its clients.With its combination of advanced technology, industry expertise, and a customer-centric approach, {Company} has established itself as a trusted leader in the world of FDM printing. For those in search of FDM printing companies near me, {Company} stands out as a top choice for high-quality, reliable, and innovative 3D printing services.In conclusion, with a focus on quality, innovation, and customer satisfaction, {Company} is well-equipped to meet the diverse needs of clients in a wide range of industries. Its dedication to technological advancements, environmental responsibility, and strong client relationships sets {Company} apart as a leading FDM printing company in the region. For those seeking top-notch FDM printing services, {Company} is undoubtedly a standout choice.

High-Quality Custom CNC Metal Services for Your Business

Custom Metal CNC, a leading manufacturer of precision metal parts, announced today the launch of their new state-of-the-art facility. The company, known for its commitment to quality and innovation, has invested in the latest CNC technology to further expand their capabilities and better serve their customers.With the addition of the new facility, Custom Metal CNC now boasts a total of 10 CNC machines, including 5-axis machining centers and multi-tasking turning centers. This expanded capacity allows the company to take on larger and more complex projects, while maintaining their high standards for quality and efficiency.“We are thrilled to announce the opening of our new facility,” said John Smith, CEO of Custom Metal CNC. “This investment represents our dedication to staying at the forefront of technology and providing our customers with the best possible service and results.”The new facility is equipped with the latest CNC software and hardware, allowing Custom Metal CNC to produce parts with tight tolerances and intricate geometries. This advanced technology also enables the company to optimize their production processes, reducing lead times and increasing overall productivity.In addition to the new equipment, Custom Metal CNC has also expanded their team of highly skilled machinists and engineers. This talented and experienced workforce is committed to delivering top-quality parts and components, meeting the demands of various industries, including aerospace, automotive, medical, and more.“We have assembled a team of experts who are passionate about what they do,” Smith added. “Their dedication to precision and their unwavering commitment to excellence is what sets Custom Metal CNC apart in the industry.”Custom Metal CNC’s dedication to quality is further exemplified by their adherence to strict quality control measures. The company is ISO 9001 certified and follows a rigorous inspection process to ensure that every part meets the highest standards of accuracy and reliability.With their expanded capabilities, cutting-edge technology, and skilled workforce, Custom Metal CNC is well-positioned to continue providing innovative solutions to their customers’ metal part needs. The company is committed to pushing the boundaries of what is possible with CNC machining, while maintaining their focus on quality and customer satisfaction.“We are excited for the opportunities that our new facility will bring,” Smith stated. “We look forward to taking on new challenges and exceeding the expectations of our customers.”Custom Metal CNC’s new facility represents a significant milestone for the company, solidifying their position as a leader in the precision metal parts industry. With their unwavering commitment to quality, innovation, and customer satisfaction, Custom Metal CNC is poised for continued success and sustained growth in the years to come.

Discover the Benefits of High Precision Machining for Your Business

High Precision Machining Company Sets New Industry StandardWith the increasing demands for high-quality machining and manufacturing services, one company has stepped up to define new industry standards. {Company Name}, a leading provider of precision machining services, has achieved unprecedented success in the highly competitive machining industry. By leveraging cutting-edge technology, skilled engineers, and a commitment to excellence, the company has solidified its position as a trailblazer in the field of precision machining.{Company Name} specializes in offering a comprehensive range of precision machining services, including CNC milling, turning, grinding, and more. The company's state-of-the-art facilities are equipped with advanced machinery and tools, allowing them to deliver exceptional precision and accuracy in every project. From prototyping to full-scale production runs, {Company Name} has the expertise and capabilities to meet the diverse needs of its clients across various industries.One of the key factors that set {Company Name} apart from its competitors is its relentless pursuit of perfection. The company's team of experienced engineers and technical experts are dedicated to pushing the boundaries of precision machining, continually seeking innovative solutions to complex manufacturing challenges. By combining a deep understanding of material properties, cutting-edge software, and advanced machining techniques, {Company Name} delivers unmatched precision and quality in every project.In addition to its technical expertise, {Company Name} places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their unique requirements and objectives, offering tailored solutions that meet and exceed expectations. Whether it's a tight deadline, complex geometries, or demanding quality standards, {Company Name} is committed to delivering results that drive their clients' success.Furthermore, {Company Name} prides itself on its commitment to continuous improvement and innovation. The company heavily invests in research and development, always seeking new ways to enhance its capabilities and elevate the standards of precision machining. By staying ahead of industry trends and technological advancements, {Company Name} is well-positioned to meet the evolving needs of its clients in an ever-changing market landscape.One notable example of {Company Name}'s innovative approach to precision machining is its investment in high-precision CNC machining centers. These cutting-edge machines are equipped with advanced features and capabilities, allowing for complex machining operations with exceptional accuracy and repeatability. By harnessing the power of these high-precision CNC machines, {Company Name} has set a new standard for precision and surface finish, enabling the company to tackle the most challenging machining tasks with ease.In an industry where precision is paramount, {Company Name} has established itself as a trusted partner for businesses seeking unparalleled machining expertise. The company's unwavering commitment to quality, precision, and customer satisfaction has earned them a strong reputation within the industry and a loyal clientele.As {Company Name} continues to push the boundaries of precision machining, the company remains committed to delivering exceptional results that drive their clients' success. With a relentless focus on innovation, continuous improvement, and customer satisfaction, {Company Name} is poised to lead the way in defining new industry standards for precision machining.In conclusion, {Company Name}'s dedication to excellence, technological prowess, and commitment to innovation have set the company apart as a leader in the field of high precision machining. As the industry continues to evolve, {Company Name} is well-positioned to continue driving the standards of precision machining to new heights. With a proven track record of delivering exceptional results, the company is poised to shape the future of precision machining and set new industry benchmarks for years to come.

High-Quality Parts for Sls Vehicles Now Available

Sls Parts, an industry-leading provider of high-quality automotive parts, has recently announced the launch of their latest line of innovative products. The company, known for its commitment to excellence and customer satisfaction, prides itself on delivering superior parts and exceptional service to its clients.With a focus on providing top-of-the-line automotive parts, Sls Parts has established itself as a trusted name in the industry. The company's extensive range of products includes everything from engine components and electrical parts to steering and suspension systems. By offering a comprehensive selection of high-quality parts, the company has become a go-to source for automotive enthusiasts and professionals alike.Sls Parts is dedicated to staying ahead of the curve in the rapidly evolving automotive industry. Their team of experienced professionals works tirelessly to develop and introduce cutting-edge products that meet the ever-changing needs of their customers. With a strong emphasis on research and development, the company is constantly seeking new ways to improve the performance and reliability of their parts.The latest line of products from Sls Parts showcases the company’s ongoing commitment to innovation and quality. Each new product is meticulously designed to deliver optimal performance and durability, ensuring that customers can rely on Sls Parts for all their automotive needs. Whether it's a small repair or a major overhaul, the company's products are engineered to meet the highest standards of excellence.In addition to their unwavering dedication to product quality, Sls Parts is also known for its exceptional customer service. The company understands the importance of providing personalized support and guidance to help customers find the right parts for their specific needs. With a team of knowledgeable and friendly professionals, Sls Parts is committed to ensuring that every customer receives the attention and assistance they deserve.Furthermore, Sls Parts takes pride in its environmentally friendly practices. As a responsible corporate citizen, the company adheres to strict environmental standards in its manufacturing processes. By utilizing sustainable materials and minimizing waste, Sls Parts is committed to reducing its impact on the environment while continuing to deliver top-quality products to its customers.As Sls Parts continues to grow and expand its product offerings, the company remains dedicated to upholding its core values of quality, innovation, and customer satisfaction. With a steadfast commitment to excellence, Sls Parts is poised to remain a leader in the automotive parts industry for years to come.In conclusion, Sls Parts has established itself as a premier provider of high-quality automotive parts, known for its commitment to innovation, quality, and customer satisfaction. The company's latest line of products reflects its ongoing dedication to excellence, with each new offering designed to deliver optimal performance and reliability. With a focus on environmental sustainability and exceptional customer service, Sls Parts is well-positioned to continue its success in the automotive industry.

The Latest in CNC Services: What You Need to Know

China Cnc Service, a leading provider of CNC machining services, has been making waves in the industry with its cutting-edge technology and top-notch customer service. Known for its precision engineering and quick turnaround times, the company has quickly become a go-to option for businesses looking for high-quality CNC machining solutions.With a state-of-the-art facility and a team of highly skilled technicians, China Cnc Service has the capability to produce complex and intricate parts with unparalleled accuracy. Whether it's prototyping, small-scale production, or large volume orders, the company has the capacity to meet the diverse needs of its clients.One of the key factors that set China Cnc Service apart from its competitors is its commitment to excellence. The company utilizes the latest CNC machining technology to ensure that each part meets the highest standards of quality and precision. From 3-axis to 5-axis machining, the company has the expertise and resources to handle projects of varying complexity.In addition to its advanced machinery, China Cnc Service also places a strong emphasis on customer service. The company prides itself on its ability to work closely with clients to understand their specific requirements and deliver customized solutions that exceed expectations. Whether it's providing design assistance, material selection, or post-machining services, the team at China Cnc Service is dedicated to providing a seamless and hassle-free experience for its customers.Furthermore, China Cnc Service is also known for its adherence to strict quality control measures. The company has implemented a comprehensive quality management system to ensure that each part undergoes rigorous inspection and testing before it is shipped to the customer. This commitment to quality has earned China Cnc Service a stellar reputation for reliability and consistency in the industry.With a focus on innovation and continuous improvement, China Cnc Service is well-positioned to meet the evolving needs of its customers. The company regularly invests in research and development to stay ahead of the curve and explore new techniques and processes that can further enhance its capabilities.Customers who have worked with China Cnc Service have only positive feedback to share. One client commented, "We have been consistently impressed with the level of professionalism and expertise demonstrated by the team at China Cnc Service. They have been an invaluable partner in helping us bring our designs to life."As a forward-thinking company, China Cnc Service is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its operations and uses recyclable materials whenever possible. This not only aligns with the company's values but also reflects its efforts to make a positive impact on the environment.In conclusion, China Cnc Service has established itself as a reliable and trusted partner for businesses seeking high-quality CNC machining services. With its cutting-edge technology, personalized approach, and unwavering commitment to excellence, the company continues to set the bar high for the industry. As it continues to grow and expand its capabilities, China Cnc Service is poised to remain a leader in the CNC machining sector for years to come.

Understanding the Benefits of 5 Axis CNC Machining for Your Business

Five Axis CNC Technology Revolutionizes Manufacturing IndustryIn recent years, the manufacturing industry has undergone a significant transformation with the emergence of advanced technologies. One such innovation that has revolutionized the sector is the 5-axis CNC machining technology, which offers unprecedented precision and efficiency in manufacturing processes.The 5-axis CNC machine, developed by [Company Name], is a cutting-edge tool that has redefined manufacturing capabilities. This technology allows for the simultaneous movement of the cutting tool in five different axes, enabling the production of complex and intricate components with unparalleled accuracy. By utilizing this advanced machining technology, manufacturers can achieve higher productivity, reduce lead times, and deliver superior quality products to their customers.With the growing demand for more intricate and sophisticated parts across various industries, the 5-axis CNC technology has become a game-changer in the manufacturing landscape. Its ability to produce complex geometries and intricate shapes with ease has made it an indispensable tool for aerospace, automotive, medical, and other high-precision industries.The [Company Name] has been at the forefront of developing and implementing this cutting-edge technology, offering a range of 5-axis CNC machines that cater to the diverse needs of the manufacturing sector. The company's commitment to innovation and quality has resulted in the creation of highly advanced machines that deliver unmatched precision and efficiency, making them the preferred choice for manufacturers worldwide.The 5-axis CNC technology has not only transformed the manufacturing processes but has also opened up new opportunities for businesses to expand their product offerings. With the ability to produce complex parts in a single setup, manufacturers can reduce the number of operations required, resulting in cost savings and improved workflow.Moreover, the precision and accuracy offered by the 5-axis CNC technology have enabled manufacturers to push the boundaries of design and engineering, leading to the creation of innovative and highly functional products. This has translated into enhanced competitiveness for businesses, as they can now offer products that were previously deemed unachievable through traditional machining methods.In addition to its impact on manufacturing processes, the 5-axis CNC technology has also had a significant influence on the skill sets required in the industry. With the introduction of advanced machines, the demand for skilled programmers and operators has increased, driving the need for a workforce that is well-versed in the intricacies of 5-axis machining.To address this growing need, [Company Name] has also invested in training and development programs to equip individuals with the knowledge and skills required to operate and program 5-axis CNC machines effectively. By doing so, the company has not only contributed to the advancement of manufacturing capabilities but has also played a crucial role in nurturing the talents that will drive the industry forward.As the demand for high-precision components continues to rise, the 5-axis CNC technology is expected to play an even more prominent role in shaping the future of manufacturing. Its ability to streamline processes, increase efficiency, and elevate the quality of products will undoubtedly make it an indispensable tool for businesses looking to stay ahead in an increasingly competitive market.In conclusion, the 5-axis CNC technology developed by [Company Name] has ushered in a new era of possibilities in the manufacturing industry. Its ability to produce complex and intricate components with unparalleled precision has transformed the way products are made, offering manufacturers the opportunity to push the boundaries of design and engineering. As the industry continues to evolve, the 5-axis CNC technology will undoubtedly remain a driving force behind innovation and excellence in manufacturing.

Custom Low Volume CNC Machining Services: Quality Parts at Affordable Prices

Low Volume CNC Machining provides high-precision production of custom parts for a wide range of industries. With a focus on quality and quick turnaround times, the company's state-of-the-art facility and experienced team ensure that clients receive the exact components they need, when they need them.Specializing in low-volume production runs, Low Volume CNC Machining is able to provide small quantities of parts with the same level of accuracy and attention to detail as larger production runs. This makes them a valuable partner for companies who require custom parts for prototypes, specialized equipment, or limited production runs.The company's CNC machining capabilities allow for the production of parts with complex geometries and tight tolerances. This gives clients the confidence that their components will perform as intended, with the precise measurements and specifications needed for their specific application.In addition to CNC machining, the company also offers a range of secondary processes to further enhance the quality and functionality of the parts they produce. These processes include surface finishing, heat treating, and assembly, providing clients with a one-stop solution for all their custom part needs.One of the key advantages of working with Low Volume CNC Machining is their commitment to customer satisfaction. From the initial consultation to final delivery, the company's team works closely with clients to ensure that their exact requirements are met. This level of personalized attention sets them apart from other machining services and has earned them a reputation for reliability and excellence.Furthermore, the company's dedication to continuous improvement and investment in cutting-edge technology ensures that they are able to meet the evolving needs of their clients. Whether it's staying current with the latest machining techniques or implementing new quality control measures, Low Volume CNC Machining is committed to delivering the highest quality parts with every project.With a track record of success across a broad spectrum of industries, including aerospace, automotive, and medical, Low Volume CNC Machining has established itself as a trusted partner for companies with unique and demanding machining needs. Their ability to efficiently produce low-volume custom parts with uncompromising quality has made them a go-to source for businesses looking for a reliable, cost-effective solution.In summary, Low Volume CNC Machining is a leading provider of high-precision, low-volume custom parts for a diverse range of industries. With a focus on quality, reliability, and customer satisfaction, the company's state-of-the-art facility and experienced team ensure that clients receive the exact components they need, when they need them. Whether it's prototypes, specialized equipment, or limited production runs, Low Volume CNC Machining is the trusted partner for all custom part needs.

The Best Material for Plastic Moulds: A Complete Guide

Plastic Mould Material, a leading provider of high-quality plastic mold materials, has been making waves in the manufacturing industry. With a strong commitment to innovation and excellence, the company has become a trusted name in the field of plastic mold materials.Since its inception, Plastic Mould Material has been dedicated to delivering top-notch products that meet the needs of its customers. The company's extensive range of plastic mold materials is designed to cater to a wide variety of applications, from automotive and aerospace to medical and consumer goods.One of the key factors that set Plastic Mould Material apart from its competitors is its commitment to quality. The company uses only the finest materials and employs the latest manufacturing techniques to ensure that its products are of the highest standard. This dedication to quality has earned Plastic Mould Material a reputation for excellence and reliability in the industry.In addition to its focus on quality, Plastic Mould Material is also known for its innovative approach to product development. The company continuously invests in research and development to stay ahead of the curve and provide its customers with cutting-edge solutions. By keeping a finger on the pulse of the industry, Plastic Mould Material is able to anticipate market trends and develop products that meet the evolving needs of its customers.Furthermore, Plastic Mould Material has a strong commitment to sustainability and environmental responsibility. The company is dedicated to reducing its environmental impact and operates with a focus on sustainability throughout its manufacturing processes. By implementing a range of eco-friendly practices, such as energy-efficient manufacturing and waste reduction initiatives, Plastic Mould Material strives to minimize its carbon footprint and contribute to a greener future.With a global presence, Plastic Mould Material serves a diverse customer base, providing its products to manufacturers around the world. The company's international reach has allowed it to establish strong partnerships with industry leaders and build a reputation for reliability and consistency in delivering high-quality plastic mold materials.Looking ahead, Plastic Mould Material is poised for continued growth and success in the industry. The company's unwavering commitment to excellence, innovation, and sustainability sets it apart as a leader in the field of plastic mold materials. As it continues to expand its product offerings and reach new markets, Plastic Mould Material is well-positioned to maintain its position as a trusted partner for manufacturers seeking top-quality plastic mold materials.In conclusion, Plastic Mould Material has earned its reputation as a leading provider of high-quality plastic mold materials through its focus on quality, innovation, and sustainability. With a global presence and a commitment to customer satisfaction, the company is well-positioned for continued success in the industry. For manufacturers seeking reliable and cutting-edge plastic mold materials, Plastic Mould Material is the partner of choice.