- Home

- Selective Laser Sintering

Top Selective Laser Sintering Manufacturer and OEM Supplier in China

Introducing the revolutionary manufacturing technology of Selective Laser Sintering (SLS), Guangdong Shunde Teamwork Model Co., Ltd., a leading manufacturer, supplier, and factory based in China, presents an innovative range of products.

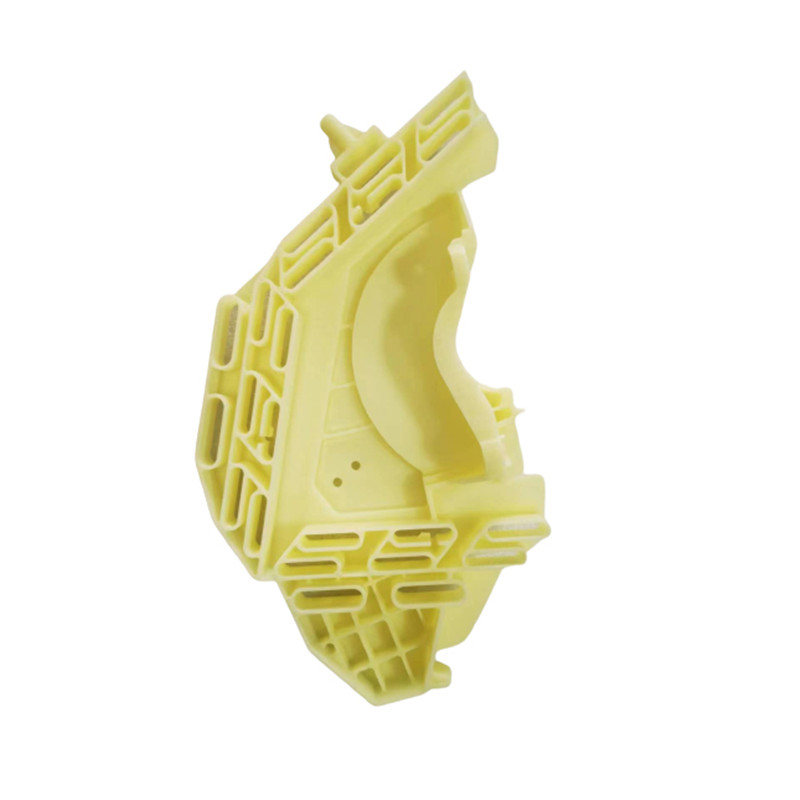

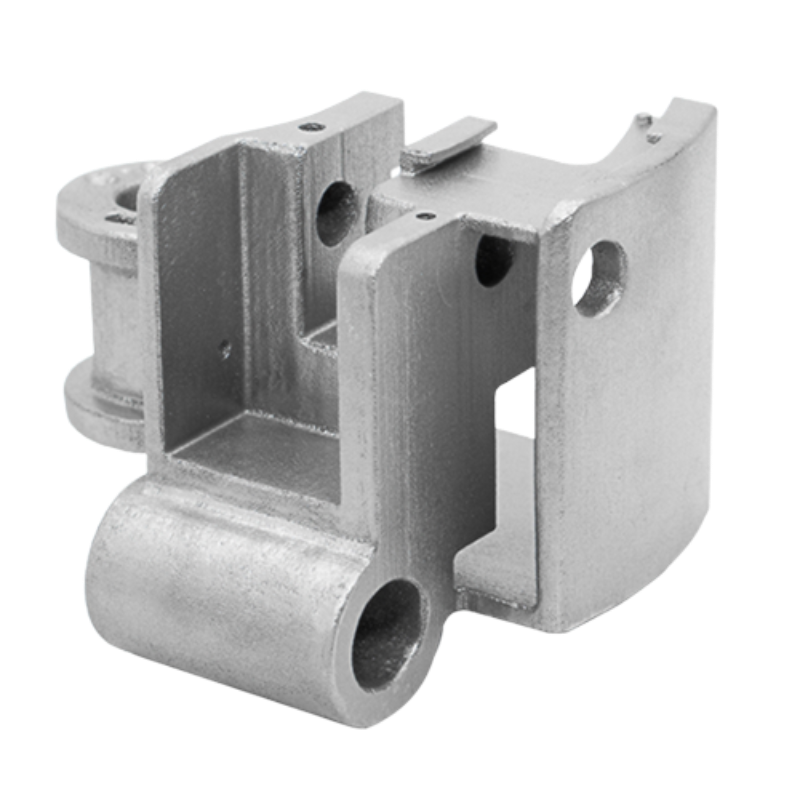

Utilizing the power of SLS, our company has revolutionized the production process by fabricating high-quality, complex components with unmatched precision and speed. Our cutting-edge SLS technology involves selectively sintering powdered material layer by layer using a high-powered laser, resulting in durable and functional end-products that meet the highest industry standards.

With SLS, we offer endless possibilities in product design and customization. From intricate prototypes to small-scale production runs, our SLS manufacturing capabilities cater to a wide array of industries, including automotive, aerospace, and medical. By eliminating the need for molds or tooling, we provide cost-effective solutions without compromising on quality or detail.

At Guangdong Shunde Teamwork Model Co., Ltd., we are committed to delivering excellence and pushing the boundaries of additive manufacturing. Our SLS technology ensures reduced lead times, increased product complexity, and enhanced overall efficiency. Choose us as your trusted partner for all your SLS manufacturing needs, and experience the future of manufacturing today.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

Customized high-quality 3D printing plastic service Chinese prototype factory

Looking for customized high-quality 3D printing plastic services? Look no further! Our Chinese prototype factory offers top-notch manufacturing capabilities and unbeatable prices. Contact us now!

OEM Manufacturing Automotive Parts Precision CNC Aluminum Machining Parts

Get high-quality OEM manufacturing automotive parts with precision CNC aluminum machining from our factory. Our expert team ensures optimal performance and durability. Contact us today!

High Precision SLA Printing 3D Printing ABS Rapid Prototype

Get high precision ABS rapid prototype parts with our professional 3D printing service. We are a factory providing SLA printing for excellent quality results.

New High Preformance 3D Printing SLS PLA Nylon Model Sample Prototype

Get top-notch SLS PLA Nylon model sample prototypes from our factory. Experience the ultimate high performance 3D printing technology for your projects.

OEM CNC Aluminum Precision Machining Components

Shop high-quality OEM CNC Aluminum Precision Machining Components from our factory. Enjoy precision, durability, and reliability in every product.

Customized metal parts stainless steel part stretching&spinning factory OEM service

Looking for customized metal parts? Our stainless steel part stretching and spinning factory offers top-notch OEM service. Contact us now!

Custom precision rapid prototype ABS plastic 3D printing parts services

Factory-direct custom precision 3D printing services for ABS plastic parts. Fast prototype production. Contact us for quality rapid prototyping solutions.

Custom CNC Machining Brass / Aluminum Prototyping Parts

Discover our factory made {Custom CNC Machining Brass / Aluminum Prototyping Parts}. Get high-quality products from a reliable manufacturer. Contact us now!

High Precision Aluminum CNC Machining Components Prototyping

Looking for high precision aluminum CNC machining components prototyping? Look no further! We are a factory specialized in delivering top-quality products with quick turnaround times.

OEM Customized 3D Printing Metal Parts Aluminum Rapid Prototyping Service

Get top-quality OEM customized 3D printing metal parts with our aluminum rapid prototyping service. As a trusted factory, we ensure precision and efficient production processes.

High Performance 3D Printing Metal Parts Rapid Prototyping Service

{High Performance 3D Printing Metal Parts Rapid Prototyping Service} - Experience top-notch metal prototyping with our factory. Fast and accurate 3D printing for high-performance parts. Order now!

OEM Home Appliance Digital Product CNC 3D Printing Prototype Chinese Factory

Looking for high-quality OEM home appliance digital products? Our Chinese factory specializes in CNC 3D printing prototypes. Contact us today!

CNC Machining Aluminum Sandblasting Customized Spare Parts Rapid Prototype

Get high-quality CNC Machined Aluminum Sandblasted Customized Spare Parts Rapid Prototypes. We are a reliable factory offering top-notch manufacturing solutions.

OEM precision 3D printed metal parts service manufacturer

Looking for top-quality OEM precision 3D printed metal parts? Look no further! As a factory, we specialize in manufacturing high-quality products. Get in touch today!

OEM Service CNC Aluminum Machining Parts Sandblasting Prototyping

Shop high-quality OEM service CNC aluminum machining parts with sandblasting prototyping at our factory. Perfect for all your manufacturing needs.

- Top Selective Laser Sintering Manufacturer in China

- Reviews

- Related Videos

Introducing our groundbreaking innovation in additive manufacturing, the Selective Laser Sintering (SLS) system. This cutting-edge technology revolutionizes traditional manufacturing processes by leveraging the power of lasers to create intricate and highly durable 3D printed products. At the heart of our SLS system is the selective laser sintering method, which allows for the creation of complex geometries and functional prototypes with unmatched precision. By selectively fusing powdered materials layer by layer using a high-power laser, our system enables the production of parts with superior mechanical properties and exceptional surface finish. One of the key advantages of our SLS system is its versatility in material usage. It can efficiently process a wide range of thermoplastic materials, including nylon, polycarbonate, and polyamide, offering flexibility in optimizing the mechanical, thermal, and aesthetic characteristics of the end product. With the ability to use various materials, our SLS system is ideal for prototyping, production parts, and customization applications across multiple industries. In addition to its material versatility, our SLS system provides significant cost and time-saving benefits. The elimination of the need for molds or tooling reduces upfront expenses and allows for rapid iteration, making it an attractive solution for businesses aiming to bring their products to market quickly and efficiently. Whether you are a designer seeking to bring your vision to life, an engineer looking to expedite the production process, or a manufacturer aiming to enhance your existing capabilities, our Selective Laser Sintering system is the answer. Experience the future of manufacturing with our SLS system and unlock limitless possibilities in design, production, and customization.

Selective Laser Sintering (SLS) is truly a game-changer in the world of additive manufacturing, and the product that utilizes this technology has left me thoroughly impressed. The precise and efficient nature of SLS allows for the creation of incredibly detailed and durable prototypes and end-use parts. The layer-by-layer process ensures high accuracy and eliminates the need for support structures, resulting in a smooth and seamless final product. The versatility of SLS enables the use of various materials, from plastics to metals, further expanding its applications. With its unmatched quality and reliability, SLS-based products are a true marvel of modern engineering.

I recently purchased a product that utilized Selective Laser Sintering (SLS) technology and I couldn't be more impressed. The precision and detail achieved with this manufacturing method is top-notch. The final product had a smooth surface finish and excellent structural integrity. The SLS process allowed for intricate designs and complex geometries which wouldn't have been possible with traditional manufacturing techniques. The durability and strength of the material used were outstanding, making the product reliable and long-lasting. I highly recommend any product that incorporates Selective Laser Sintering, as it truly delivers exceptional quality and performance.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours